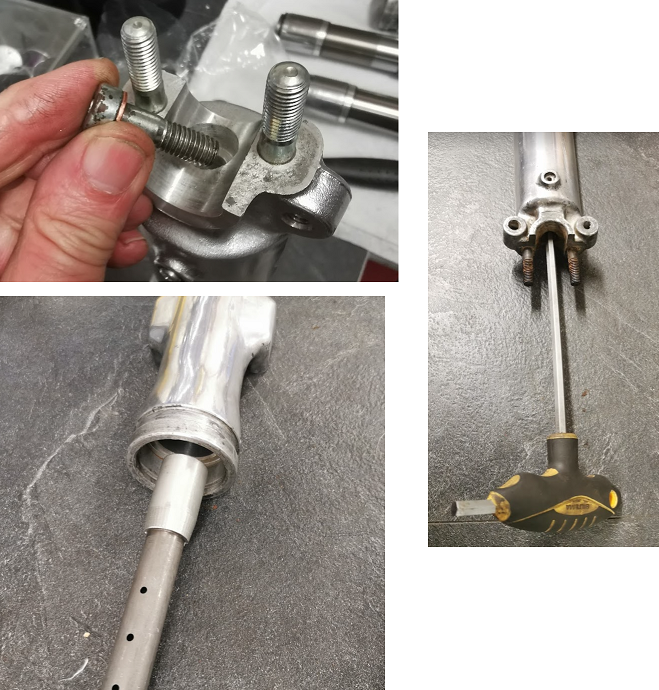

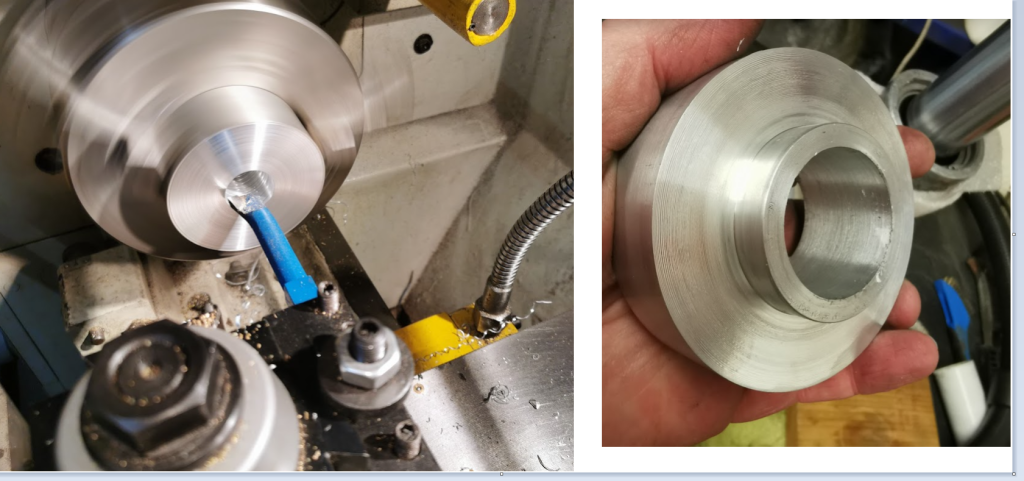

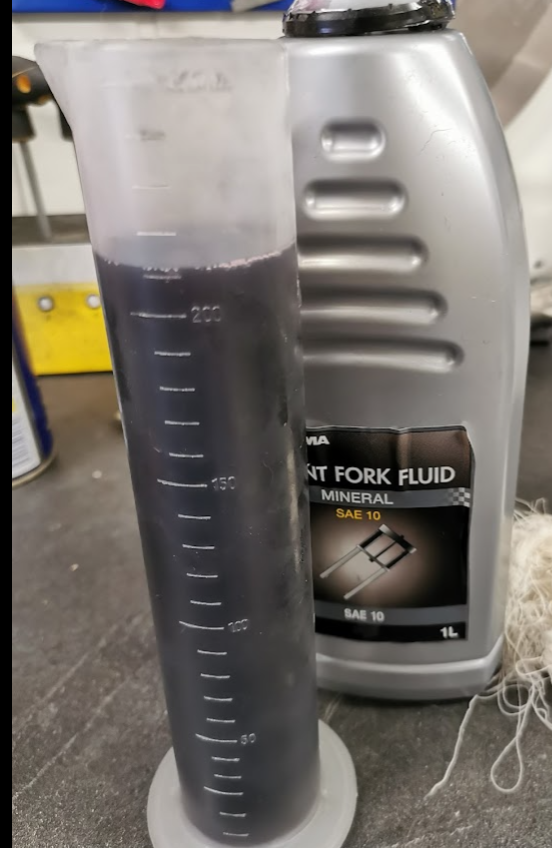

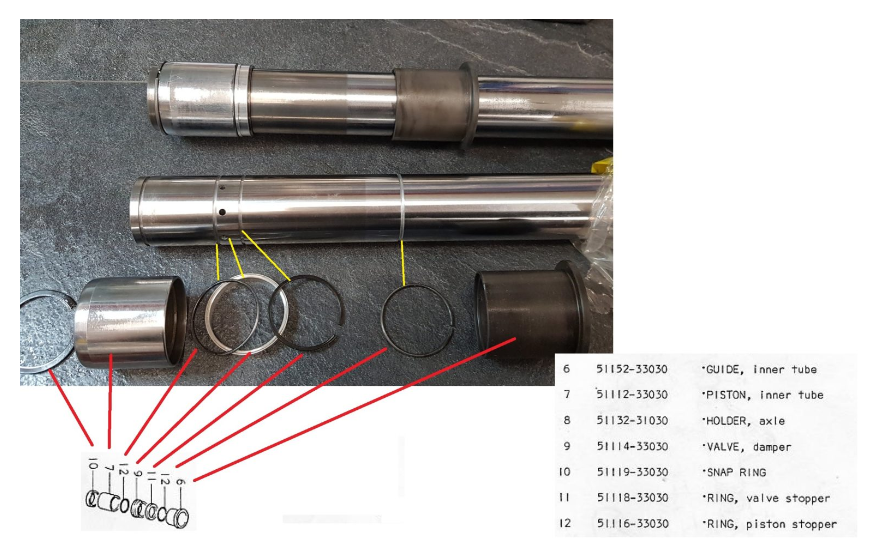

Mounting the fork

The fork was mounted according to the parts manual (GT380k)

Parts no can be found in the manual, go to the: Documents at my blog.

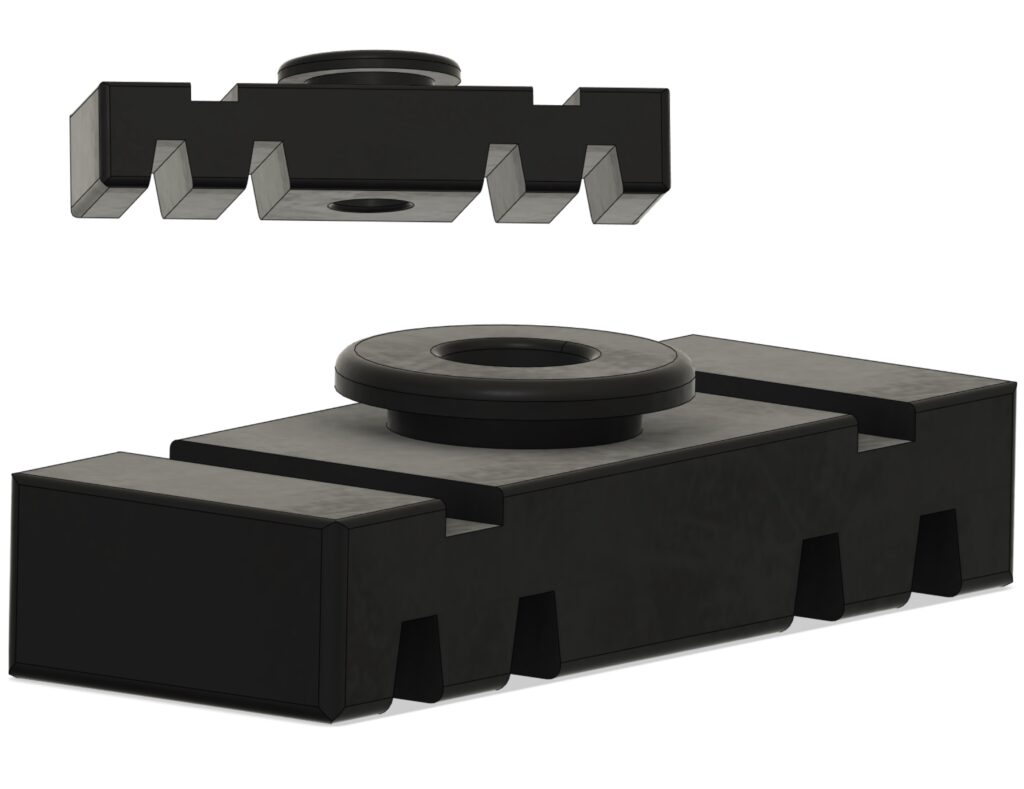

Resin print of 51553-3300:

I was missing some cushion parts. I only had one of the cushion for the headlamp bracket, the: 51553-3300

The resin 3D printer had some issues this time printing rubber resin, not sure why but still able to use the parts. I also tested the filament printer using flexible filament. Not 100%, but ok to be used.