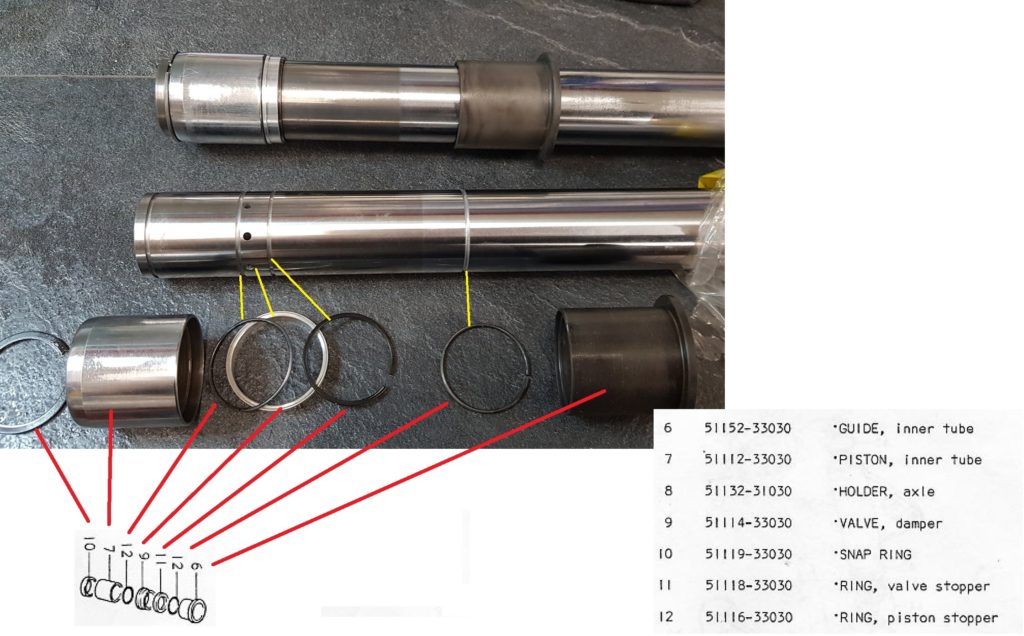

Assembly of the front fork

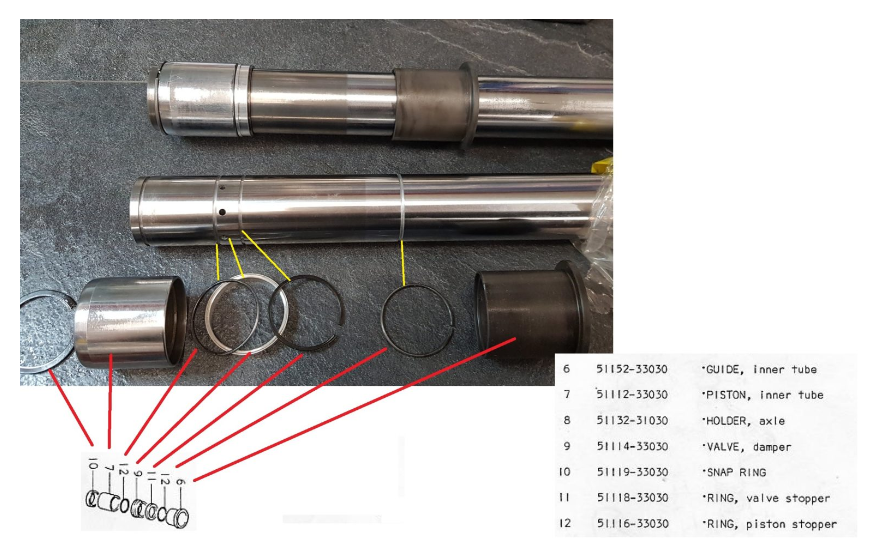

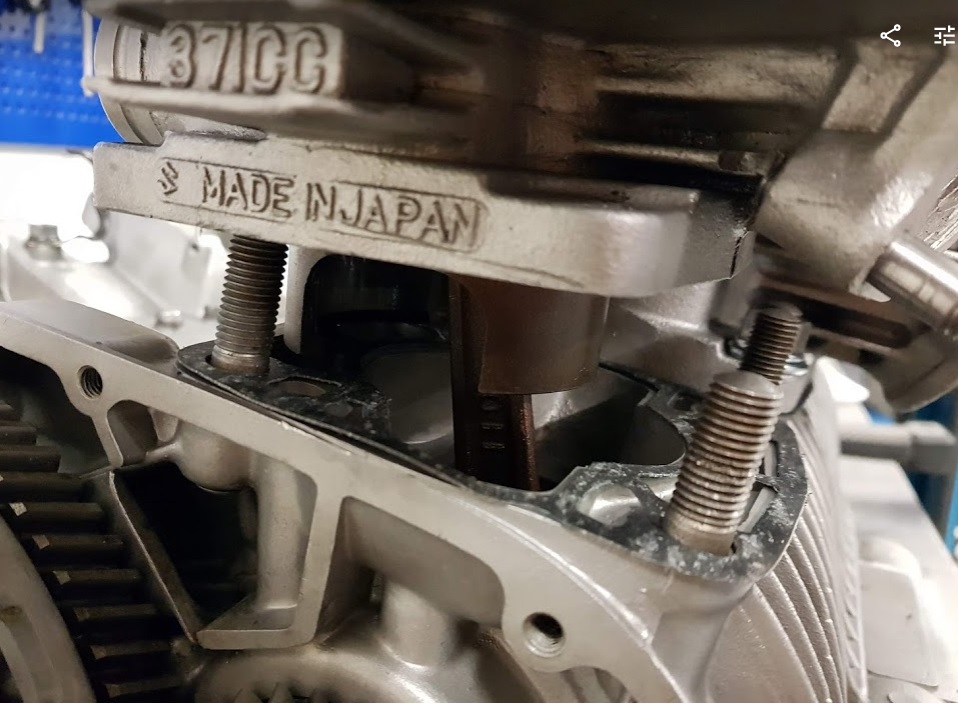

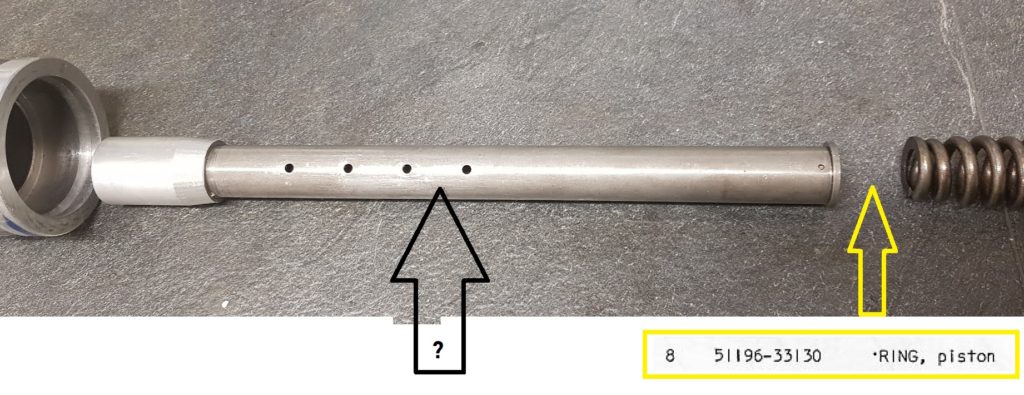

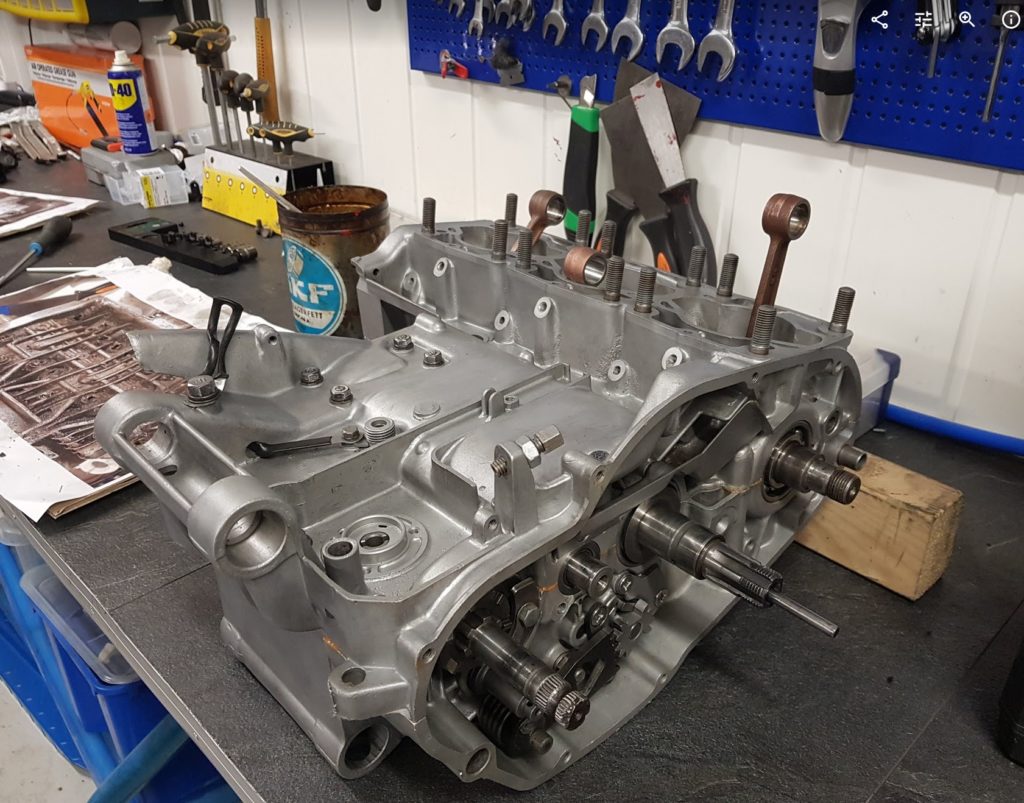

Mount the damping rod (unknown part no) into the outer tube. Don’t forget the copper washer.

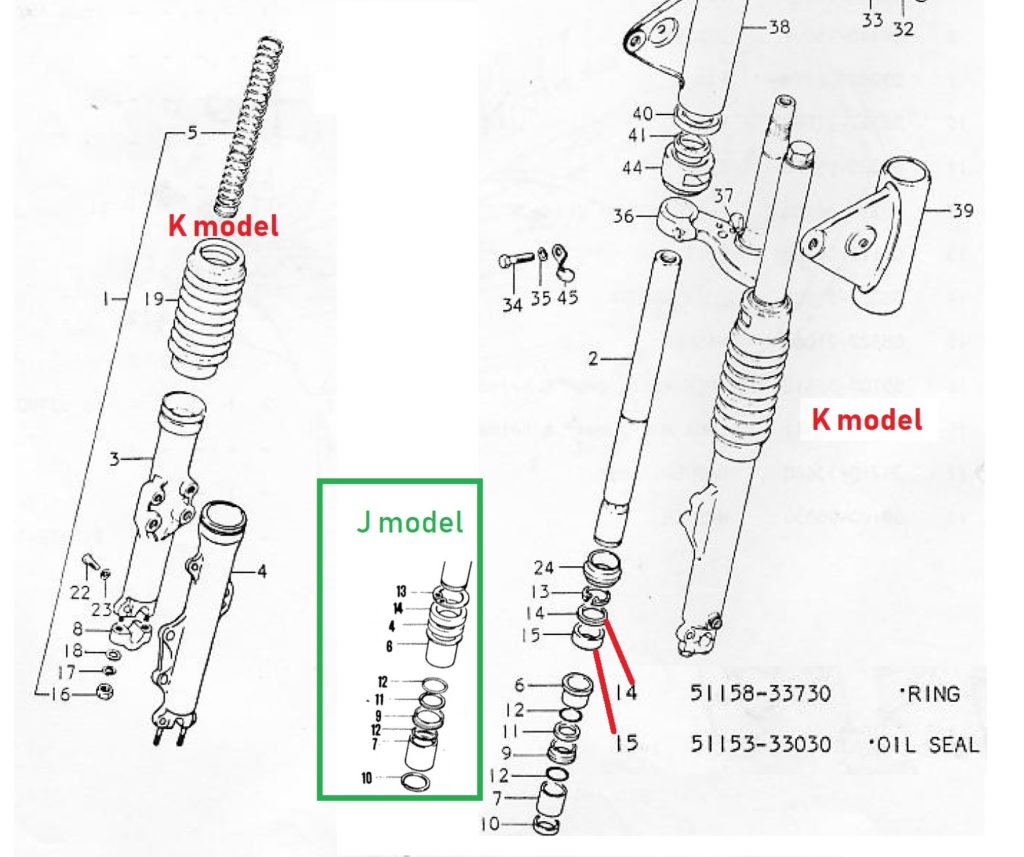

Oil seal:

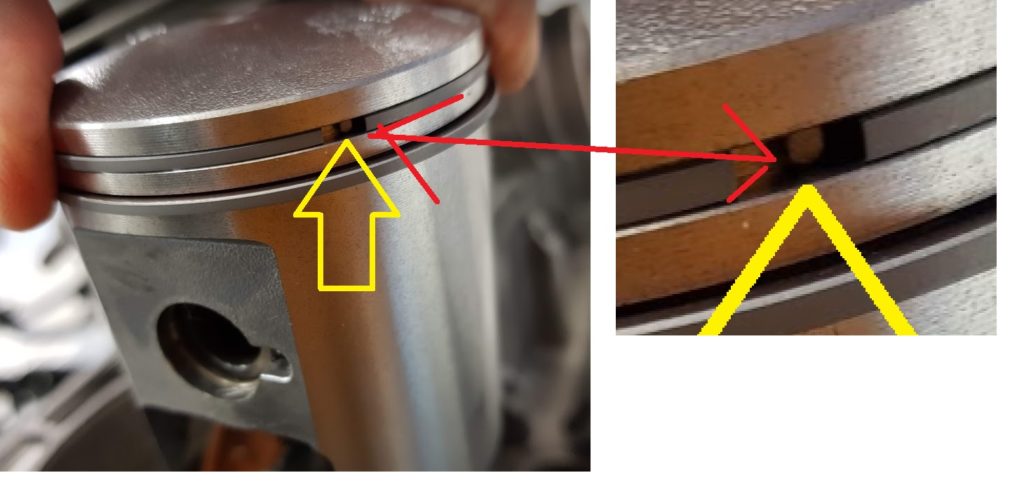

Mount the inner tube and slide the oil seal down to the outer tube.

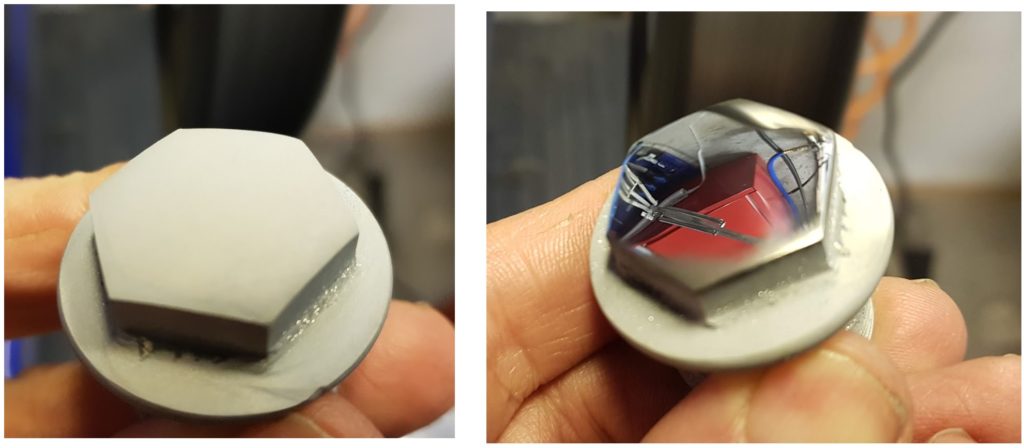

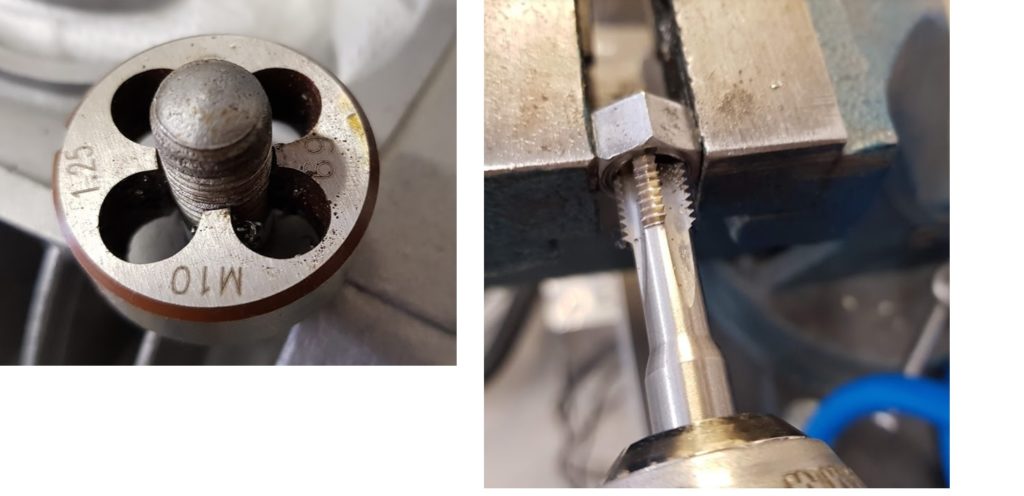

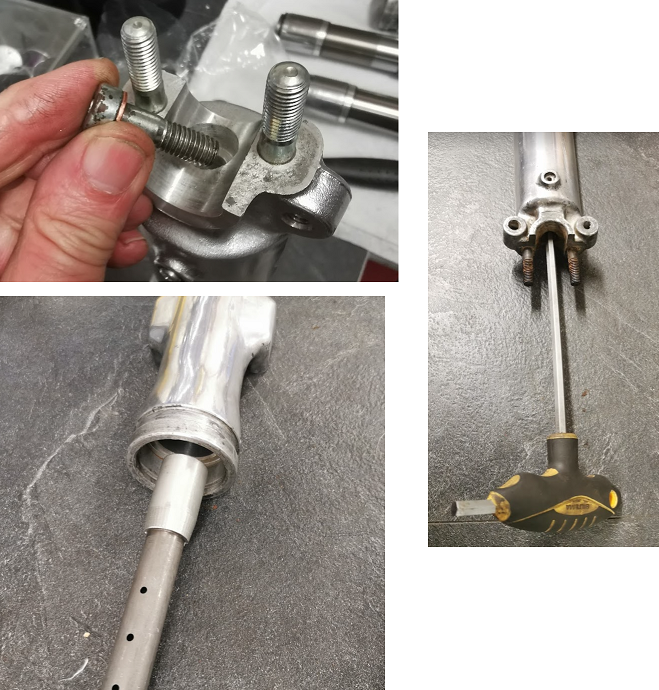

Next step can be difficult. Apply som grease around the seal, but it can be hard to drive the oil seal all the way down to the bottom. I did it “my way”

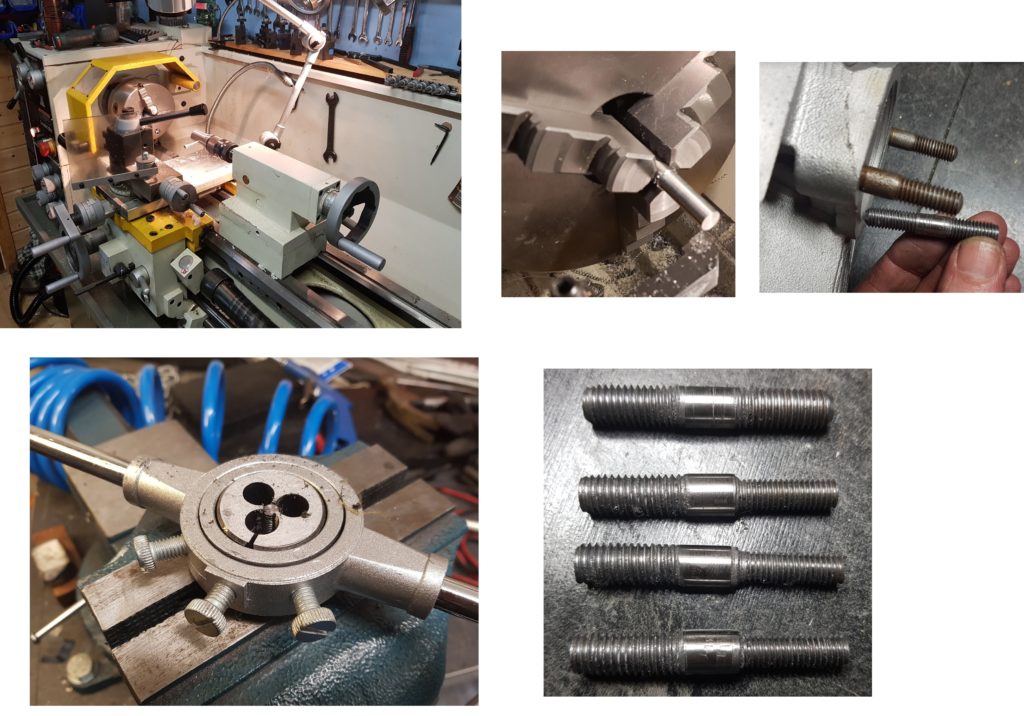

Since I have a lathe, I made a tool for the purpose.

With a plastic tube on top of the tool and a hammer it was easy to drive the seal all the way down.

Secure the oil seal with the circlip and the spacer.

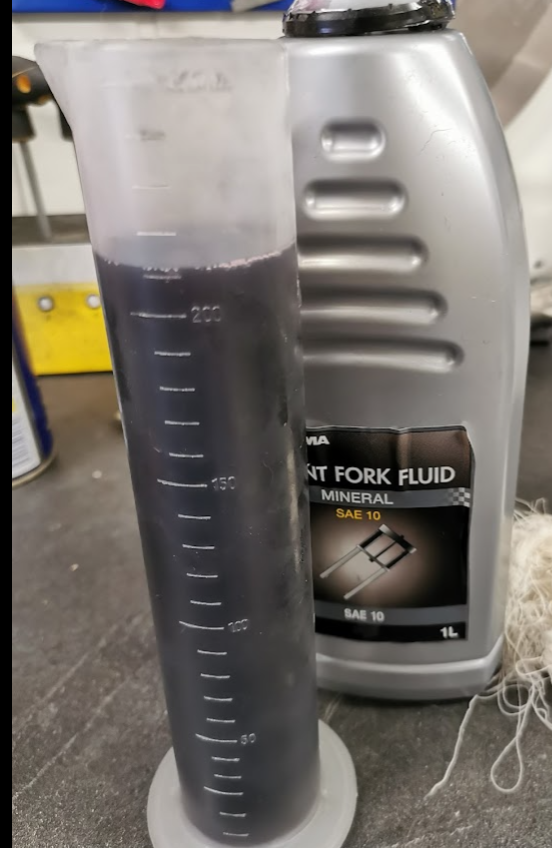

Fork oil:

Install the fork spring and apply 210ml of oil. Screw on the top bolt and you are done 🙂

Don’ forget the drain screw at the bottom.

Mounting the fork boot:

This part turned out to be very difficult. The lower end of the boot was very stiff and not flexible at all, and looked too narrow to get around the outer tube.

Soften the boot with hot air helped, and by using some plastic stripes as a guid I was able to squeeze it on.