Mounting the oil pump

For about two months ago I tested several oil pumps in the test jig I made. I decided to go for the early version of oil pumps with suction. That was the one giving best result when idling. I got scared about the others giving little or noting at low throttle.

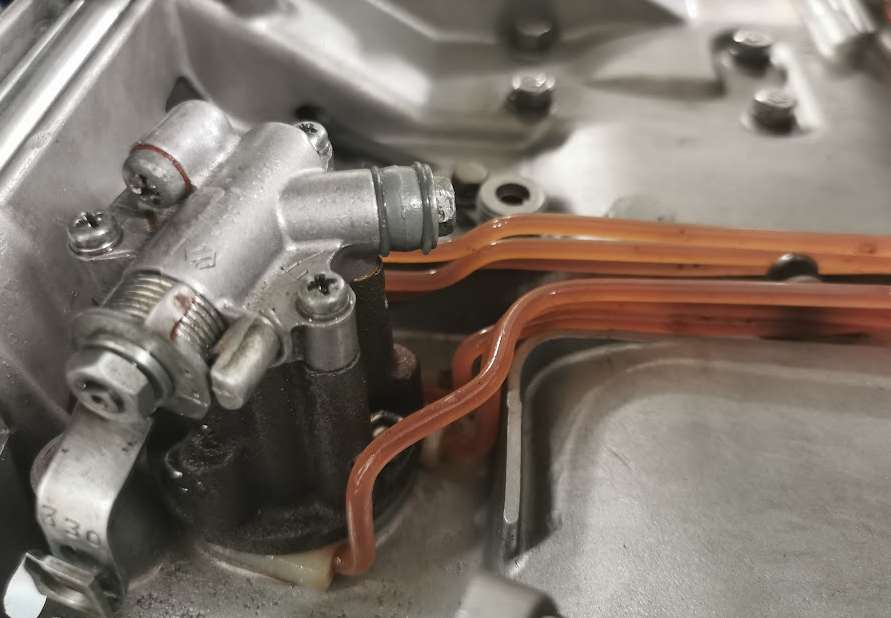

All o-rings were replaced and the same with the nylon spacers.

The 50 years old plastic and the oil-lines are very fragile, and I didn’t do much to clean or make it look nice. I knew it all worked since I had it in the test jig with good results. To drive the plastic base all the way down I prefitted the screws for holding the oil pump.

Torque settings for the banjo bolts is difficult to find. I did some investigation back in 2016 when rebuilding my GT750A and found a number of 2,5Nm. That’s lower than I today have on my smallest wrench. At that time I stole a key from my work, but this time I used common sense and was gentle to the bolts.

By using a syringe I was able to inject the oil all the way to the end of the pipes.

I have the original screws for mounting the oil pump, but I went for 5mm bolts with hex head instead. Much more easy to mount and the screw are not visible when the covers are on.

Done: