Footrest, rear and front

Rear footrest:

I bought new rubber for the footrest. The metal parts were sand blasted, sanded and nickel platet.

The lock pins were missing but I made new ones from brass using my lathe and they were nickel plated.

Front, right side footrest: (this parts for the J-K modes are hard to find)

Left and right side have different part numbers. The right one has a the groove at the front side, see the picture above.

Front, left side:

The groove is on the bottom side.

Fuel tap

The early models have three outputs from the fuel tap to each carburetor. The later models have one output to a rack mounted manifoil distributing the fuel to the carbs.

There are three fuel filters. One for the main tank and one for the reserve tank. The last one is in the bottom and can easily be maintained and cleaned.

How to test the function:

The valve in the tap is vacuum driven. Here is a simple test setup to verify its function:

I’m using a syringe to make the vacuum for opening the valve. I let the denatured alcohol stay in the upper syringe over night to be sure there were no leakage at the ON postion. When moving the lower syringe the vacuume open the valve and it all works fine. Please watch the video:

If the fuel tap is not working you can strip it down, clean and replace parts (if you can find a new part).

I swapped some parts from the later model, but most parts are different. I was only able to swap the bottom filter + the gasket.

The bottom filter:

Looks like the filters are the same on all models.

Petrol tap switch:

The gasket behind the cover is different on J-K models compared to later models. Don’t waste money and buy the wrong one.

This is the correct type of gasket for the J-K model. The hole at the center is smaller on the early models + layout of the channels are a bit different too. You can’t swap the gaskets from later to old models.

If you have a leakage, the tension of this spring located under the cover can be the issue. If the movement of the arm feels to loose, bend the spring a bit to make a better tension to the gasket.

How it all works:

ON postion:

Main tank will flow to the vacuum valve (as the arrow on the picture in the middle show)

RES postion:

The RES will flow to the vacuum valve.

PRI postion:

The RES will flow to the PRI (direct to the carbs bypassing the vacuum valve)

Vacuum valve:

If you open the vacuum valve, be sure to assemble correct. The hole in the diaphragm have to fit to the gasket and hole shown in the picture above.

Replace the o-ring in the valve if needed.

Mirror

Was lucky to get hold of the real thing. Genuine Suzuki mirror with the S-mark.

The threads were wrong, 10mm, but should be 8mm. I made adapters in brass using my lathe, and thereafter they were nickel plated and mounted on the bike.

8mm outside and 10mm ( fine pitch) internally.

8mm

Nickel plated, still using my 13 years old nickel bath.

Carburettors GT380 J-K

Time to start the overhaul of the carbs. The first time I’m doing this, so it has to be learning by doing + take a lot of photos and watch YouTube.

Sorting out the cables and carbs:

L, M and R :

This carburetor is the 33011 type. The last letter will be L, M og R for Left, Middle and Right.

Remember to organize all parts in boxes and don’t mix between L,M and R.

Removing the throttle valve:

Uncrew the top and slide off.

Removing the throttle cable and return spring:

Remove the throttle cable from the valve.

Return spring:

Remove the return spring.

Removing the choke ( starter piston):

Remove and inspect the starter valve (choke)

Remove the Drain plug and the inspection bolt for the throttle valve.

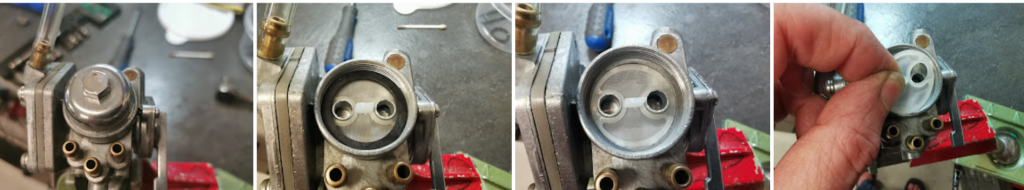

Removing the float, float valve and seat:

Inspect the valve for any worn.

Removing jets:

Needle jet:

Insert a screw and give it a tap with a hammer to get loose. Remove from the other side.

Note: The needle jet is also named Needle nozzle in the manual.

Ultrasonic cleaning:

Wather blasting:

After the ultrasonic cleaning I got all the alu parts wather blasted, looks very nice 🙂

Next step will be the assembling process, but not today.

Assembling:

All channels were well air blasted, cleaned with solvent, and air blasted again.

Mounting the needle jet (Needle nozzle):

I made a tool in brass for a more easy way to insert the needle jet. Please be aware of the lock pin and the orientation of the needle jet. Insert the jet from the other side and give tap the tool gently if needed.

Mounting the Main Jet:

Use correct size (with) of the washer. If it’s too narrow, the Needle nozzle can slide out. As shown in the picture above the Main jet will also lock the Needle nozzle in place.

Hard to see how it can slide through on the other side, working against gravity, but can happen during the assembling process it the carburetor is turned upside down. But as mentioned above, the main jet will lock it all in place if the spacer has the correct diameter.

The standard Main jet size is 0,8mm, marked as 80.

Mounting the pilot jet:

#22,5 size according to the manual.

Mounting the Air Jet:

Turn the Air jet all the way in, than 1,5 turn backwards.

Note: The picture is from the left carburetor. For the M and R, the jet is fitted from the other side.

Mounting the Idle Jet:

Did some cleaning and polishing before mounting.

Gasket:

I used the old gasket as a template, drew the outline and cut a new one in 1mm gasket material. Seems to fit quite well.

Float:

Warm the water almost to the boiling point and dip the float into the hot water.

To check the float for leakages ( it’s 50 years old and fragile) put in hot water and look for bubbles. Locate the hole and clean well before soldering.

This is not easy to fix. Clamp the part gently so it doesn’t fell apart due to the pressure inside when heating up.

Mounting the Float Seat and valve:

You can use the old one if it’s not worn.

Mounting the Float and Float Pin:

The float height will be adjusted later on when I have all three carbs ready.

Almost done:

A simple test to see how it all fit together. I think I have learned a bit so far. Hopefully the images can be at help for other as well. At least for me, when I’m doing the M and R carburetors. But not tonight.

Drain plug and inspection screw:

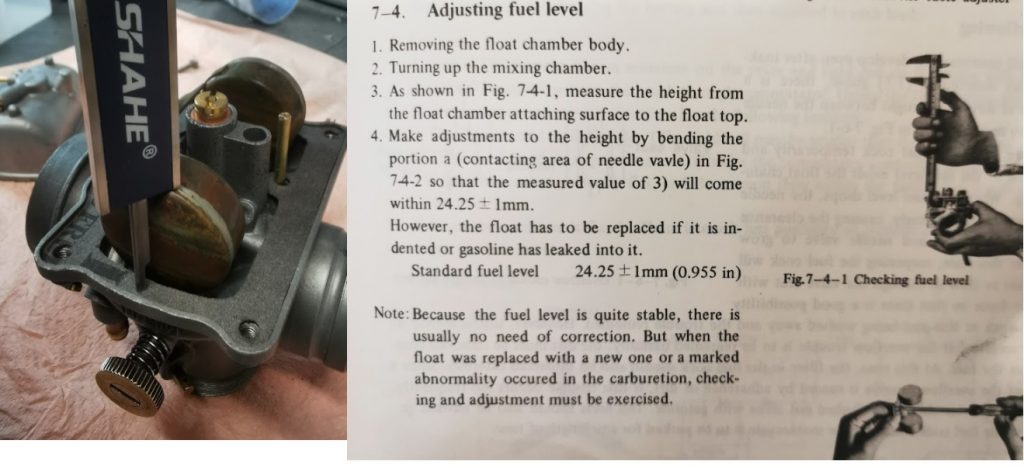

Float height :

Adjusting the fuel level according to the service manual.

Needle jet height:

The circlip at the needle jet for the center carburetor should be in the middle position. For the right and left carb, mount the circlip in the second groove from the top. This will give a bit more fuel to the center cylinder.

Rubber hose:

Replace the rubber hose if it’s old and hardened. I got them all new and the yellow arrow shows the directions for mounting the rubber hose.

Mounted on the bike:

Before routing the throttle and choke cables I mounted them all on the bike. Will buy new clamps for the rubber hoses so it all looks nice shiny.

Front brake switch

Don’t even think about it, assembling the brake switch from below. The the spring will jump away along with rest of the small parts.

Turn the brake lever upside down. This is valid for GT750 as well.

I know, the nut and the bolt for the brake lever is wrong. Will be replaced later on when I get the parts. I have to use what I have to get going.

Make sure the switch moves freely to both positions.

Add the contact disk of the switch.

Mount the plastic enclosure and make sure you have a good strain relief.

Zip ties

I use reusable zip ties at this stage for an easy adjustments if needed.

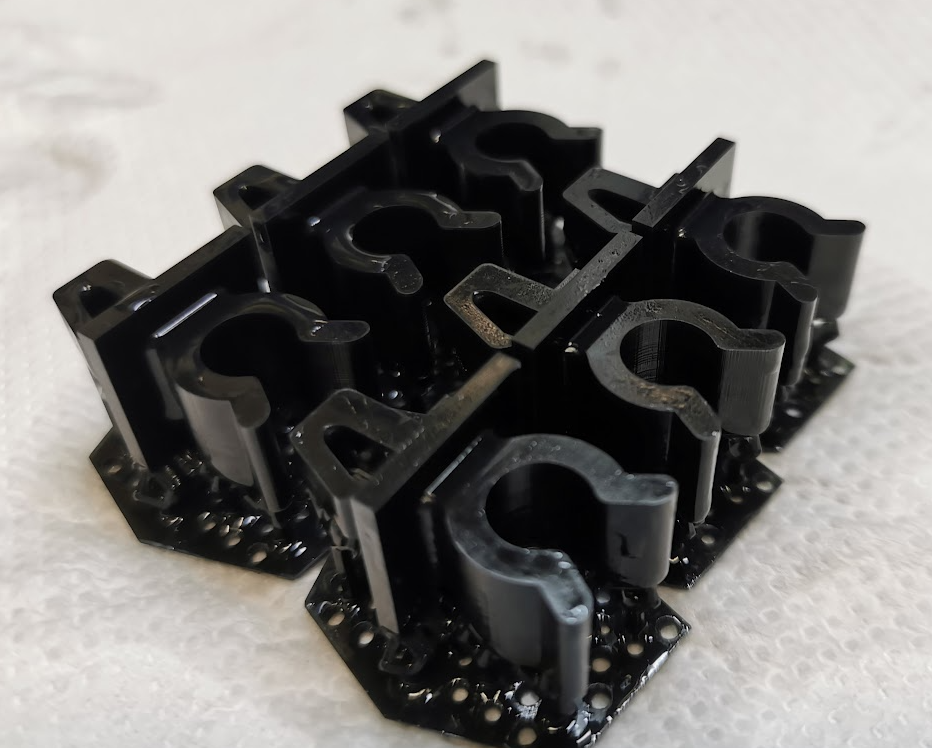

GT380 Side Cover Clip

09403-07306

Two of the old clips were broken and new parts are still available for buy. Will cost time and money to buy and since it’s fun to make my own parts, why not give it a try? The model was done in Fusion 360 and the first set of six parts were 3D printed with black resin.

The parts looks stunning, but the function of the flexible clips were not good enough. Too fragile and got easily broken. Another type of resin must be used for this type of parts. I can use my rubber resin, but I will order some ABS like resin and give it another try.

The model drawing in Fusion 360

The STL file of the part can be downloaded for free for anyone:

This post will be updated with the result of the ABS flexible resin print when it’s done. The same if I do a rubber resin print of the part.

The ones I made worked fine, but as mention above they all looked fragile and some broke when mounted into the frame.

New updates: The file above is now updated to V2 release and will fit better into the frame. The new printed part using ABS like resin was also much better.

Coils

Before and after refurbishing

The coil wiring was in a bad shape like the rest of the electronics. Wrong colors on the wires and missing connector.

If you don’t know how the coils and ignition is working, please have a look at my post i did 8 years ago when working on my GT750:

How to start: All parts were dismounted and cleaned. I was not able to clean the coils properly so I decided to paint them white.

The metal brackets holding the cables were sandblasted and nickel plated.

I had to use impact driver to loosen the screws. Don’t forget to use JIS tools ( Japanese Industrial Standards)

The bracket was sandblasted and polished.

All of the wires had to be extended or replaced. Each individual strand in the wire must be sanded before soldering. After soldering the joint was covered in epoxy and painted.

The other end of the wire got new terminal and was crimped.

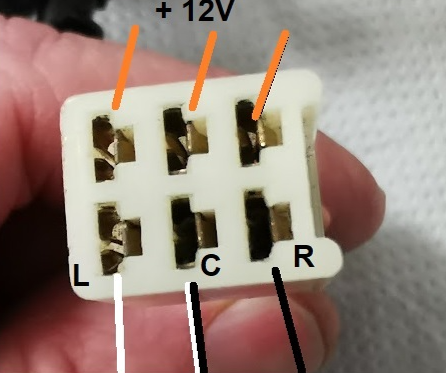

This is the color coding and placement of the wires into the connector.

The orange wires are all connected to a common +12 supply and the placement on the upper row does not matter. On the lower row, it’s very important to do it right, if not the bike will misfire on wrong cylinders.

Mounted with new wires and connector.

Before mounting I also did a spark plug test to verify all of the coils. Connect 12V to the orange wire and short the other wire to GND( 0v). The body of the spark plug must also be grounded. When you release the wire from ground the park plug will fire. ( Just tap the wire on/off to GND and you will see the spark) Do the same on all coils to verify the function.

The resistance in the coil winding should be around 4,5 ohm. The current in each coil when grounded will therefore be 12V/ 4,5 ohm= 2,7 Amp. That’s the reason why you drain the battery very fast when leaving the ignion on and the bike is not running.

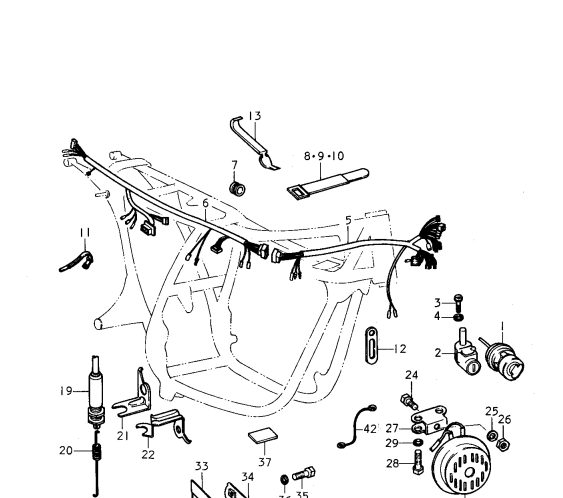

Wiring harness GT380

Hmm, a lot of questions but few answers.

According the the parts manual it looks like the wiring harness should be installed on the right side of the bike, or… not, right side must be wrong. I’m told it right is right, but based on feedback with images I have only got photos from GT380 owners with the wiring harness on the left side of the frame, and it’s the same on my GT750 too. The drawing above must a guidance of how the wiring are connected, not which side it’s fitted.

Based on photos I have got I have some idea about how it should be done. Some advice can also be found on YouTube, but you can’t trust them. Some might be right and some are wrong, and others are horrible wrong.

So, to summarize: I’m not sure, and in some case I don’t have a clue, but I have to start and will use common sense when I have to make decisions. I think a look at mye GT570 will be at a good help. As long as I make it all in compliance with the wiring diagram it should be fine.

Connectors and tools:

I bought a kit from China with a lot of different type of connectors + the crimping tool needed.

In addition I got hold of the upper and lower wiring harness and only need to make some few extra cables to fit into the harness.

The cable from the alternator is already done, please see my previous post. The same for the cable from the ignition electronics (the points )

Next up was the battery cable. That became a bit tricky. Was not able to find the old cable anywhere and how to make a new one. The corresponding connector is made of rubber and how can I make that ? Same procedure as before. I drew the part in Fusion360 and fired up my 3D printer with rubber resin. And here is the result:

I found a picture of the cable on internet and did the measurements on the mating connector from the wiring harness. After printing the part I glued the terminals and added heat shrink to the wires.

The STL file for printing can be downloaded for free:

Next step:

I inserted the main cable for the upper harness through the lower hole in the headlamp and the upper hole will go to the clocks and and switches on the handlebar. I will use adjustable cable ties for clamping the cable onto the frame so I can easy move and do changes as I continues with the wiring.

That’s enough for today. Will continue another day 🙂

Another day:

Still winter in Norway and I will spend some time in the Man Cave to do some wiring:

Still not sure how to lay down the wiring, but I give it a try and use reusable zip ties for an easy adjustments.

Head lamp wiring loom:

Pushing all the wires back into the headlight house to free up as much space as possible. Will be a tight fit later on when the headlight shall be mounted.

Hmm, something is wrong… The blue connector is not part of the schematics. Can it be for a later model with gear indicator ? No, the color code is different.

Some minutes later: Mystery solved, see the picture below:

The blue connector is for all of the small lamps in the clocks. According the the schematic it should be individual connectors, not a common one for all of the lamps. Anyhow, now I know how to do the wiring. It’s more easy too with one 6-pins connector, but why is it not part of the wring ?

Phuu, for a while I thought the main wiring loom was wrong. Well, a bit wrong. It’s not the wiring loom for the J-model and not for the latest ones either. Not a big deal since I know how to wire it and have the tools and parts to make the mating connectors.

Instruments bulbs:

One of the bulbs sockets looks horrible, and the wiring is in a bad shape as well.

I think I order new sockets and make a complete new wiring. If so,I have to 3D print the rubber cover too.

When it’s done, it will be a separate post about how I did it. I can’t put this old and ugly bulb loom back into the lovely bike.

Clamping to the frame:

Photos from the wiring layout:

Tried to lay the wiring close to the frame away from the air filter and other parts to be mounted later.

The wiring loom is quite stiff and to avoid too much bend I ended up laying down the cable as the picture shows. Probably not like the original, but I think this will work fine. But doing so, the fuse holder will fit better on the right side, close to the tool box, but why not?

I will 3D print a bracket for the fuse holder. The fuse holder is not the original, but close to. A 20A fuse.

Grounding:

Make sure the threads are clean without any paint to ensure a proper grounding.

Less questions, all the wiring are now sorted out :

The upper wiring loom I bought deviate from any standard GT380 wiring, it has some extra connectors.

Extras:

In addition to the 6-pins blue instrument lamps connectors there are two connectors with Gray and Black/white wires. for instruments lights ( tachometer and speedometer light)

One red wire with +12V, direct from the battery + pole and one extra GND wire. Can be used for alarm system or a charge port to the battery.

One green/yellow wire in the same connector going to the ON/OFF switch. Not in used for my J-model.

One brown wire. The same wire as going to the tail lamp. This wire will also be at power it the ignition switch is turned to parked position.

On/off switch:

The on /off switch is a bit difficult to spot on the wiring diagram, except from the GT380B wiring. The color code is quite simple. Orange is the +12V after the ignition switch (red before the ingnition switch). The orange/white is the +12V to the coils and the bike will of course never run if this switch is turned off. According to the GT380J wiring it’s the orange/white wire changes to solid organge from the switch connector and down to the coils, but not on later models. A bit annoying and I’ve seen several variants of the J-wiring diagrams. Not easy to know what is correct.

A summary of the color codes:

Red (R): The +12V from the battery through the 20A fuse.

Orange (O): +12V after the ignition switch

Orange / white (O/W) 12V + after the ON/OFF switch. Turn on /off the voltage to the coils. Note! only orange wire on earlier models (According to the schematics)

White (W) : Brake lamp wire.

Brown (BR) Tail lamp.

Gray (GR) Instruments lamps

Blue (BL) Neutral position switch. The indicator lamp will light if the wired is shorted to ground.

Light Green (LG) Right indicator lamp.

Black (BK) Left indicator lamp.

Black/white (BK/W) GND (Ground, connected to the frame)

Light Blue (LBL) Turn signal relay wire.

Yellow in the rear wiring (Y) 3 phase AC voltage

Yellow in the front wiring (Y) High Beam Head Lamp.

Note: The Gray and Brown wires will be shorted by the ignition switch in run position and both the indicators lamps and tail lamp will light (if the main light switch is on). If the ignition switch is left in parked position the orange and brown wires are shorted and the tail lamp will light (regardless of the main light switch).

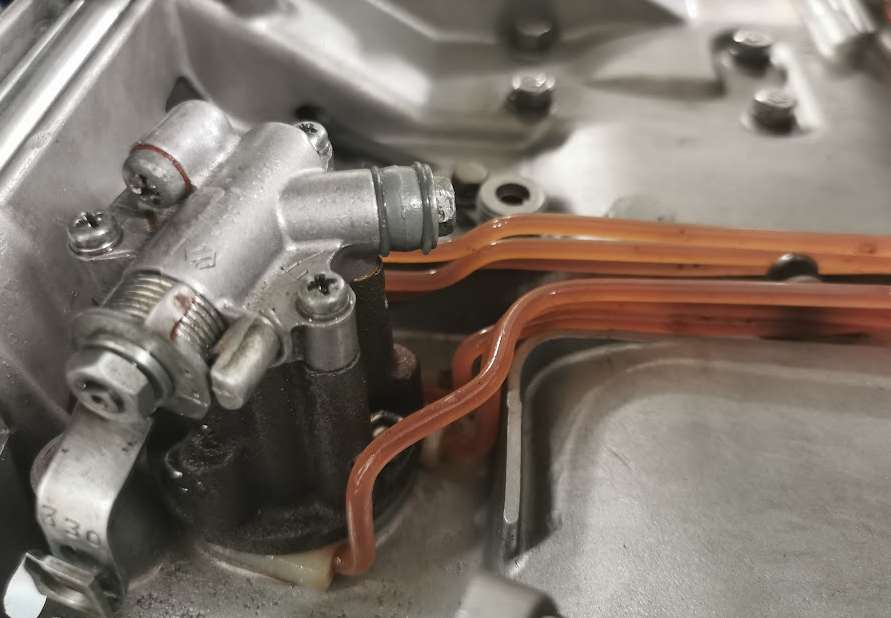

Mounting the oil pump

For about two months ago I tested several oil pumps in the test jig I made. I decided to go for the early version of oil pumps with suction. That was the one giving best result when idling. I got scared about the others giving little or noting at low throttle.

All o-rings were replaced and the same with the nylon spacers.

The 50 years old plastic and the oil-lines are very fragile, and I didn’t do much to clean or make it look nice. I knew it all worked since I had it in the test jig with good results. To drive the plastic base all the way down I prefitted the screws for holding the oil pump.

Torque settings for the banjo bolts is difficult to find. I did some investigation back in 2016 when rebuilding my GT750A and found a number of 2,5Nm. That’s lower than I today have on my smallest wrench. At that time I stole a key from my work, but this time I used common sense and was gentle to the bolts.

By using a syringe I was able to inject the oil all the way to the end of the pipes.

I have the original screws for mounting the oil pump, but I went for 5mm bolts with hex head instead. Much more easy to mount and the screw are not visible when the covers are on.

Done: