Neutral Switch GT380J-K

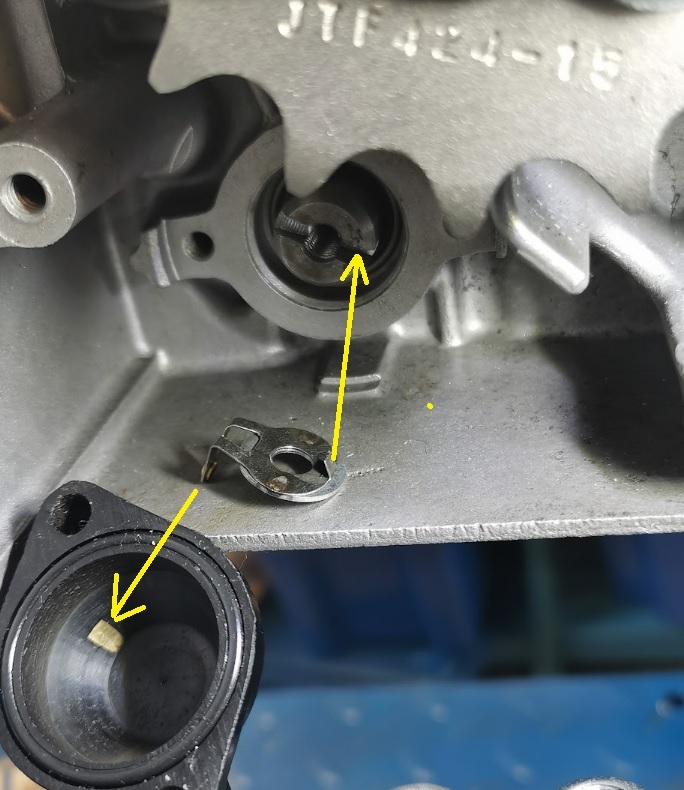

The picture above shows the function of the neutral switch. The shifting switch (Part 44) is attached to the gear shifting cam. In neutral position the switch will reach the contact point inside the housing (part 39), this will lead to shortening the blue wire down to ground. Since the lamp in connected from the blue wire to +12V, the bulb will light up in neutral position.

Make sure the contact points are cleaned and polished at the inside and outside of the housing. I added a new washer and screw too.

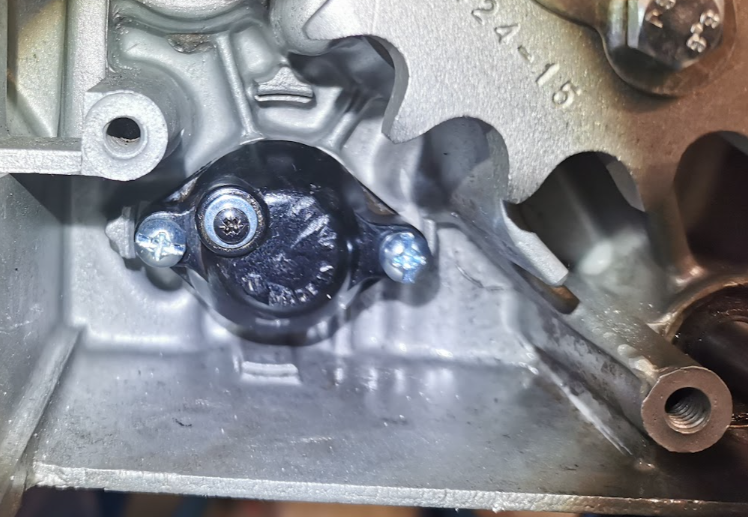

Before mounting, put the engine into neutral position. Make sure the switch is mounted with the lip into the groove at the end of the shifting cam. If so, the contact point in the switch will meet the contact point in the housing.

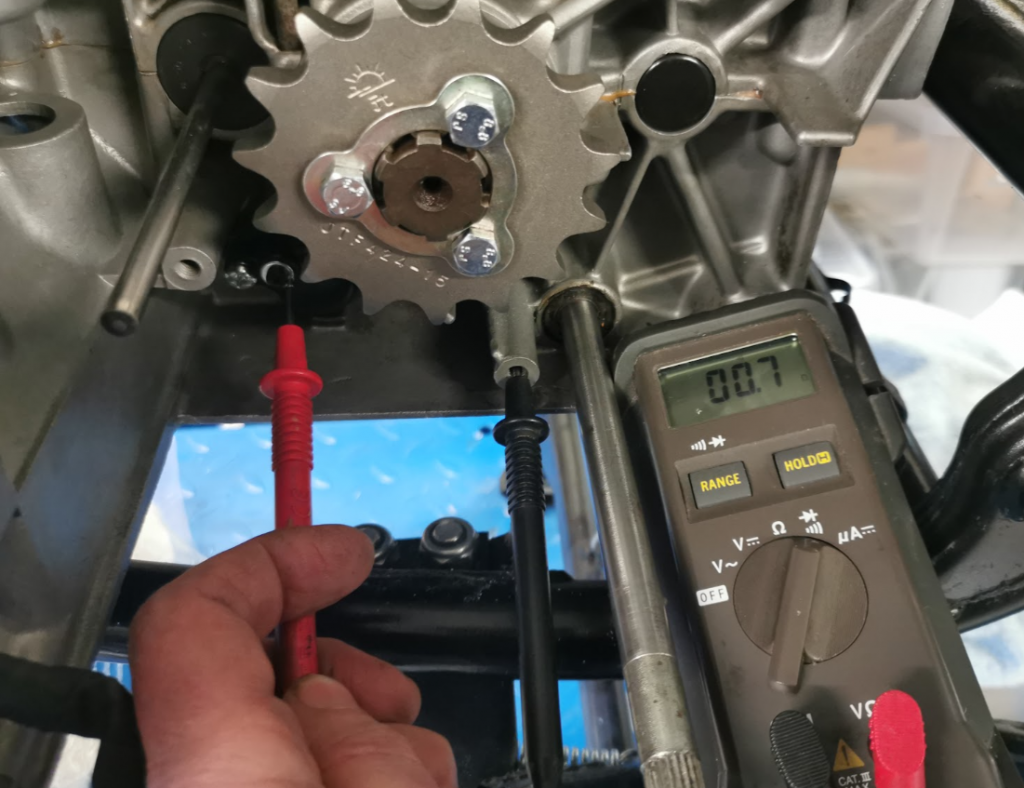

To verify the function, measure the conductivity from the witch down to GND. Should be a short (close to 0 ohm) when the engine is in neutral position.

When you add the wiring harness, the blue wire from the alternator cable should be fastened to the switch.

Rectifier

GT380 schematics

The figure above is a copy from the wiring diagram. It shows the 3-phase rectifier with three yellow wires as AC input and the plus (red wire) and GND(ground 0V black and white wire) as DC output.

The wiring diagram also shows the housing (one of the heatsink) is grounded.

Note! I had a look on my GT750A model. An other type of rectifier (the smaller one) and the black and white GND wire is missing. All the grounding is done direct through the mounting bolt. Only four wires, three yellow and one red to the connector. A bit confusing, because the detailed wiring diagram for GT750 shows the GND wire, but not in the owners manual for GT750A. I assume it’s done different from 72-77 models.

GT750A version, no black & white GND wire.

If you are uncertain how the rectifier works with all 6 diodes, please review my previous post about the alternator for GT750 and GT380. There you will also find link to YouTube explaning how it all works.

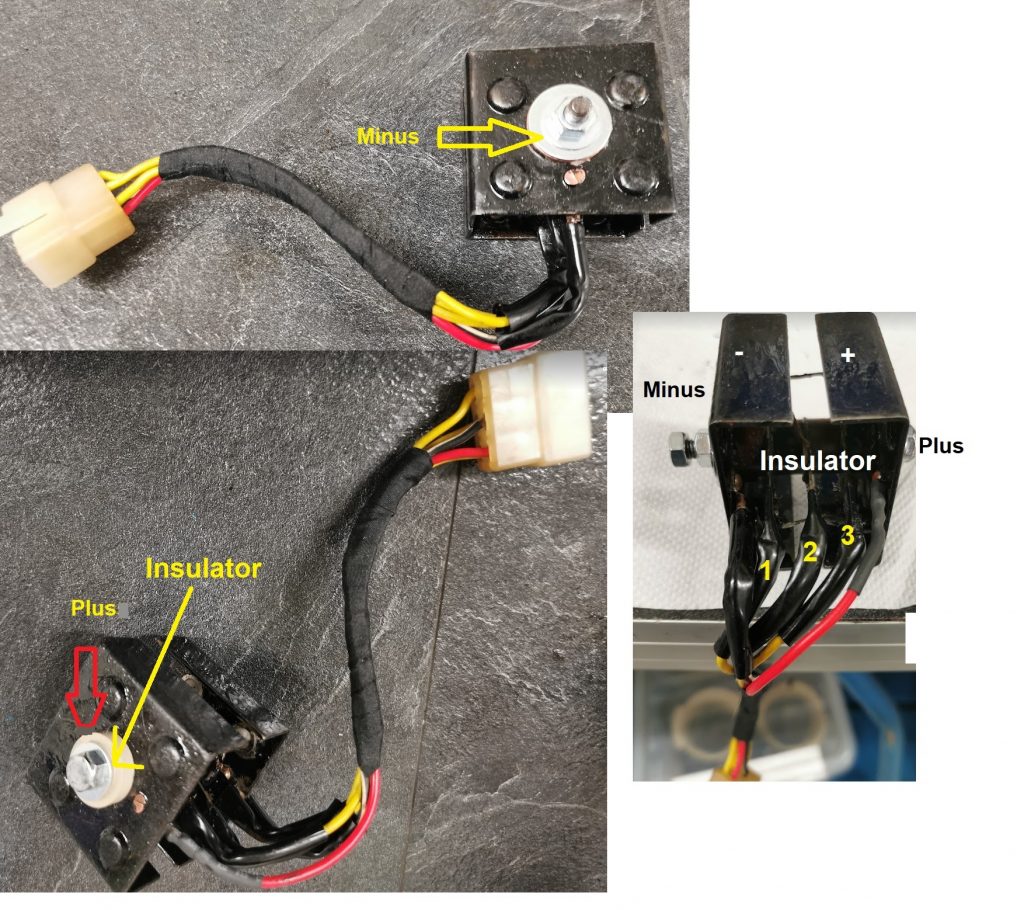

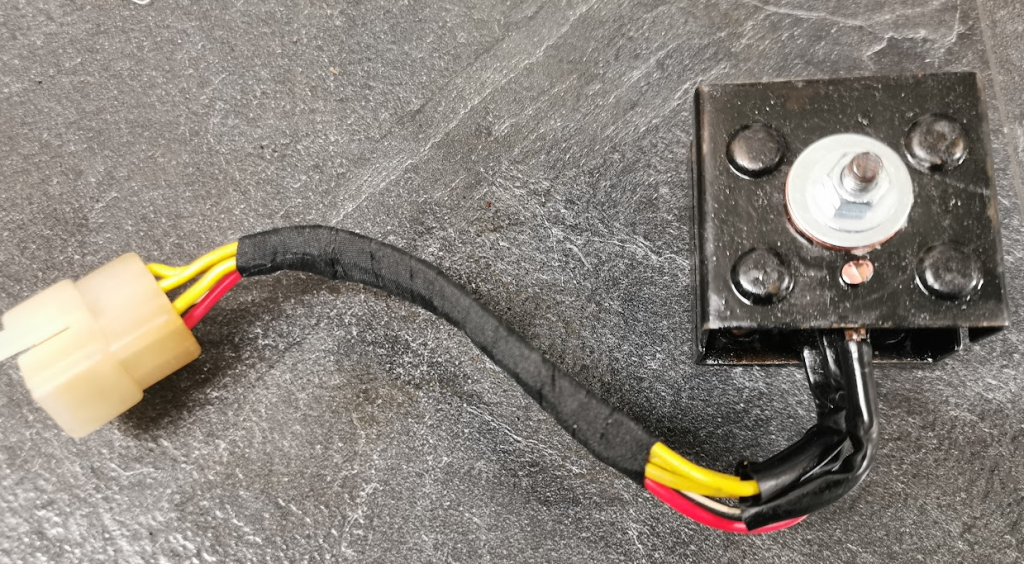

The rectifier in the image above is from the J model. You can might find a different package on later models with smaller heatsink, but they all works in the same way.

You have six diodes, three with the anode connected to the case and three diodes with the cathode connected to the case.

Please note, the rectifier has the heatsink splitted in two parts. One is the pluss output ond the other one the minus output (GND) . If you scratch off the pain from the positive heatsink and by accident short the heatsink to GND you short all of the voltage to ground on your bike. Note! the heatsink is connected to plus, not the bolt. The image shows how the bolt going thrugh is insulated. I did a small mod using making the insulator in peek material to improve the design a little bit.

The other part of the heatsink shall be grounded to GND according to the schematics. Mine was not and I’m not sure if it was wrong mounted or it is common not to do do. Anyhow, both options will work, but if not grounded all of the current to GND has to go through the black and wire to GND. I did it in my way and made better connection to GND from the heatsink.

Remember to remove paint to achieve a proper connection to GND.

All of the connectors where polished and the red wire who was broken got replaced with a new wire and connector.

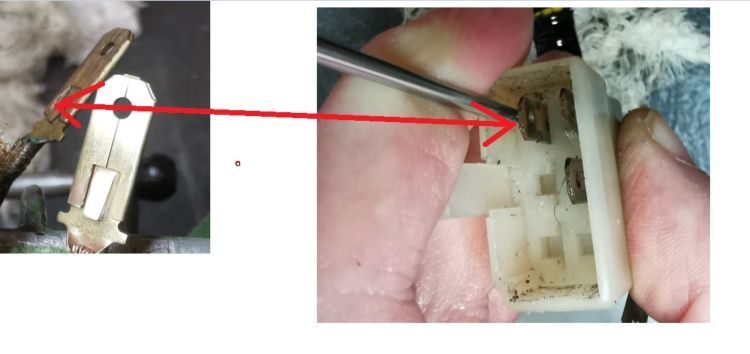

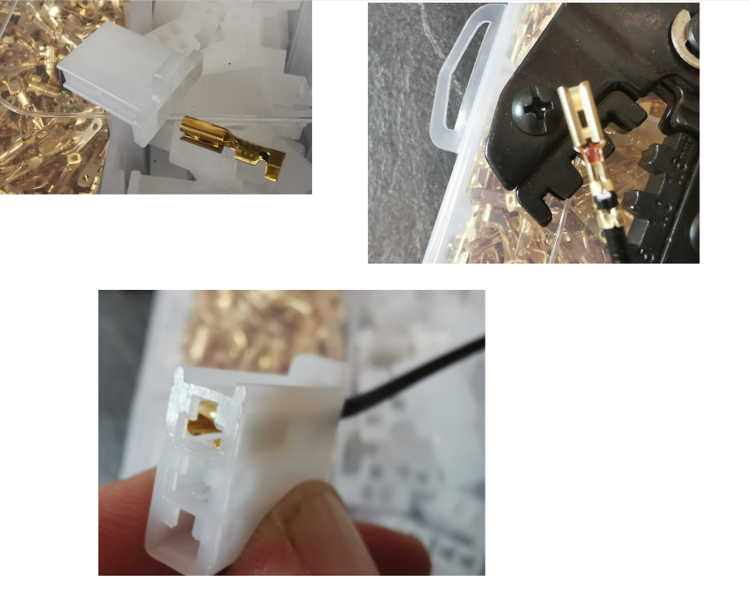

To remove the terminal from the connector, use a flat screw driver to bend the lip down and pull the terminal out from the rear side. Remember to bend the lip back to normal position when inserted.

Diode testing:

When using a multimeter for testing, switch to diode testing and do the measurements. Positive terminal(red test lead) on the anode and negtive terminal (black test lead) on the cathode. Measure all six diodes, but keep track of anode and cathode. Since the three of the diodes have the anode to GND you can also measure to the heatsink insted of the black and white GND wire/treminal

The instruments shall give you a value for about 0,45V, and no voltage if you swap the terminals ( positive on cathode and negative on anode).

Measure all six diodes, but keep track of anode and cathode. Since the three of the diodes have the anode to GND you can also measure to the heatsink insted of the black and white GND wire/treminal.

If you don’t have any multimeter you can use a small 9V battery as input and and a test lamp at the output. When you swap the polarity on the 9V battery applying power to the yellow 3-phase input the lamp shuld still light, and do the same betwen all phases.

Done !

Oil pump

This post will be about the oil pump, for both the GT750 and GT380, old and new models.

The information below is my understanding based on testing and iformation given to me. If something is wrong, please let me know and I will updatate my blog.

Some basic informations:

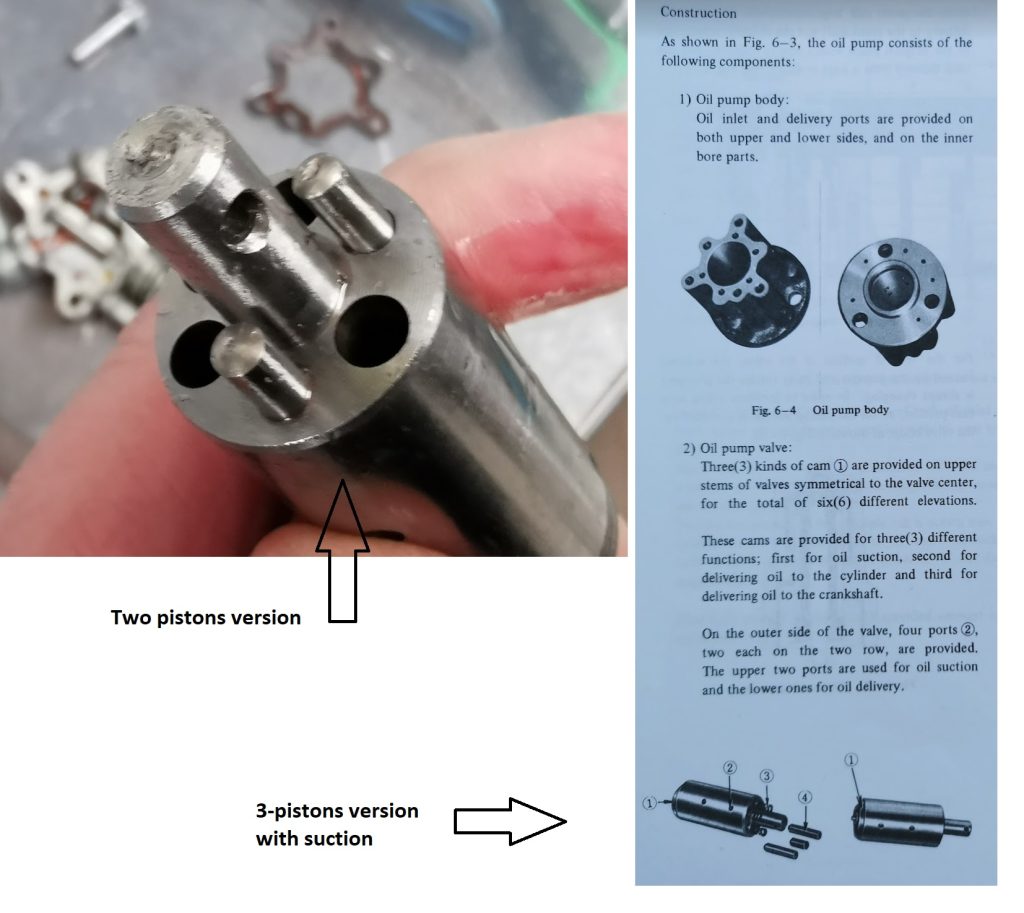

As the picture above shows we have an early model of the pump using one extra piston for suction. On later models the gravity from the oil tank above the thank do the job, and Suzuki decided to make it more simple with only two pistons.

Note! Never,ever go away from using the oil pump and only mix oil into the fuel, if so the crankshaft will not be lubericated.

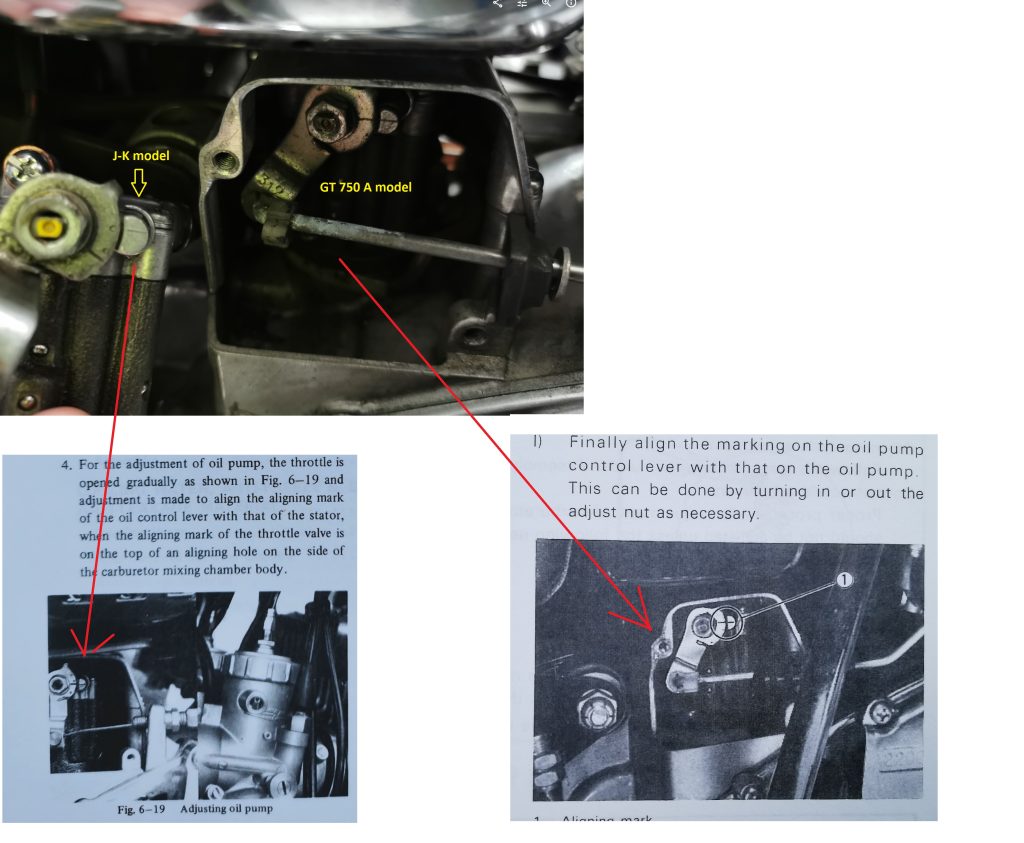

Are all pumps interchangeable ? Yes, all of the GT380 to GT750, old and later models, but there are some differences. Later models for GT750 using the vacuum carbs have a different arm connecting the throttle cable, see the picture below:

The punch mark and alignment marks are at different location (order) on J-K (GT750 models and all GT380 models) compare to the latest GT750 models. The alignment procedures are also differnt, see the picture above and the service manual.

Test setup:

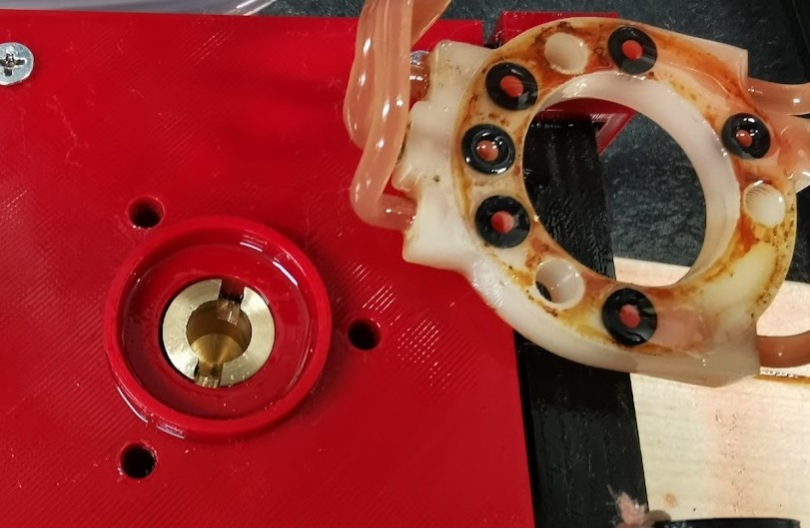

The speed of the pump is controlled by a DC motor and most of the parts are 3D-printed.

The shaft running the pump is made of brass and locked in position by two ball bearings.

Lesson learned after the testing:

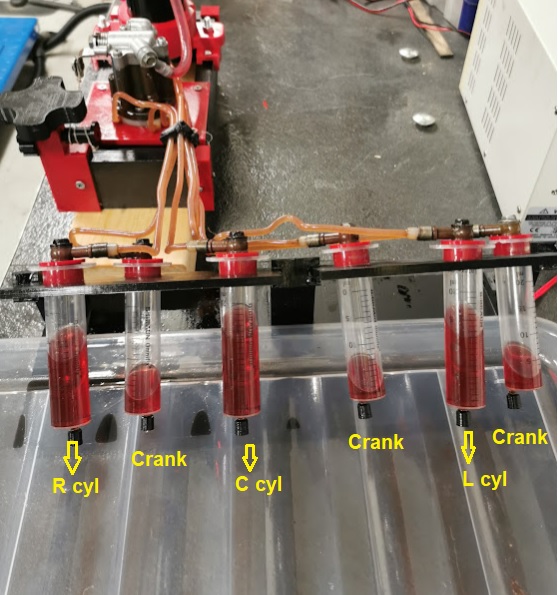

At normal operation the cylinders get more oil compare to the crankshaft, but one important observation:

At the first punch mark there are almost no oil coming to the cylinders, only to the crank. On my test with two later models with only two pistons and no suctions, this was the case. A bit scary to watch. On the early model with three pistons and suctions I got a bit of oil to the pistons at the first punch mark as well, but no much. As soon as I increased the throttle it all worked as normal. Most of the oil to the cylinders and less to the crankshaft.

In the video below the pump is running between the first and second punch mark.

On my GT750 the oil consumption is close to 100ml per. 100 km, as it should be. In test above the rpm of the pump is 1hz ( 60 rpm) and refer to the engine that will be about 4000 rpm. The consumption from the test looks very much the same as I see on my GT750, but the 3-piston pump with suction gives a bit more.

Gasket:

I ordered new gasket from E-bay, but to start the testing I made my own by scanning the old one and cut new with my laser cutter:

Seems to work fine. Since I have paid the money for new ones, I might swap the gaskets when they arrives.

Copy from the manual:

Contact Breaker Assembly

(Denso type)

Note: Points or breakers are the same. I usually refer to the breakers calling them points.

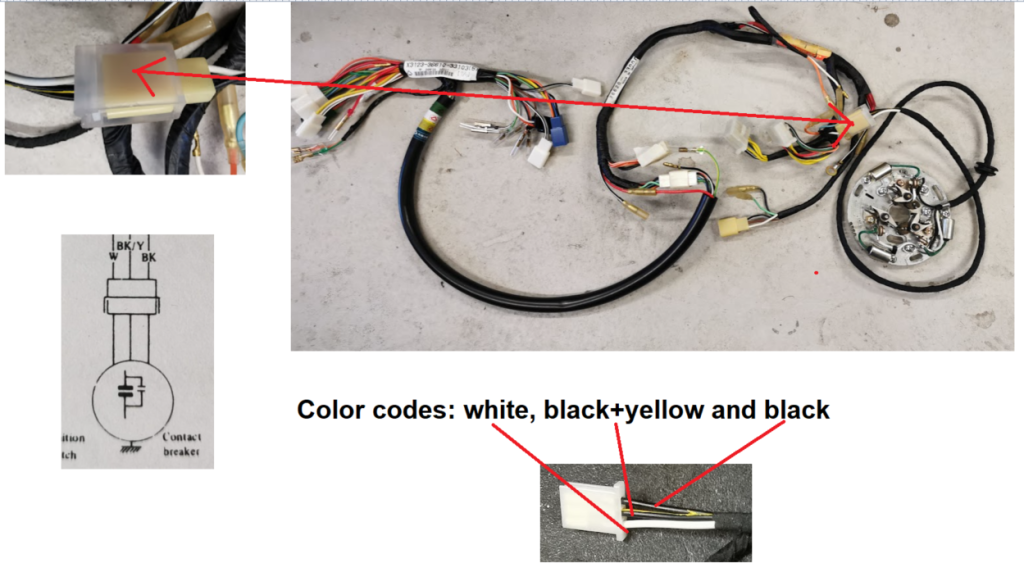

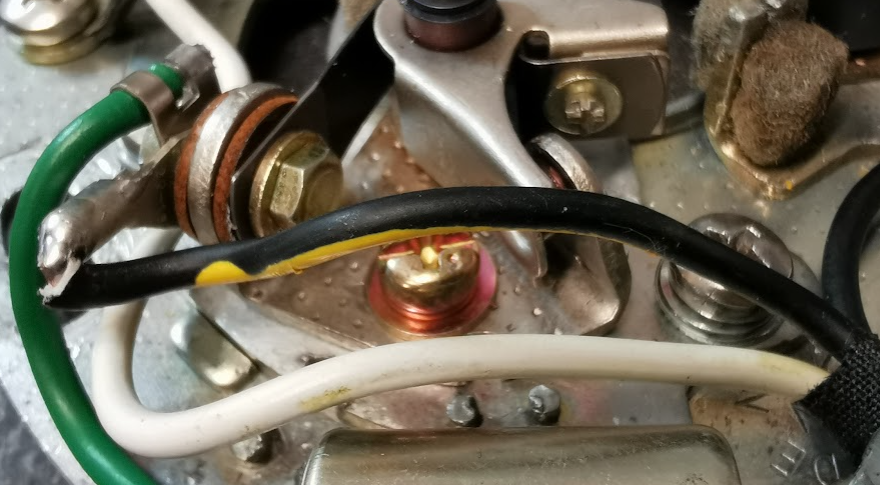

As mention before, my GT380J project was in a horrible state when I bought it. No exceptions when it comes to the electronics. Wrong connectors and terminals. Wrong color codes on many of the wires. The wiring for the contact breaker was a mess too and I had to make it all new according to the wiring diragram.

This is how it was, wrong wire colors, wrong type of screws, and missing connector.

By the way, be aware of the difference from GT750 to GT380. Since the points are located on the right side of the bike on GT380 and left side on GT750, they have to be mirrored. Don’t buy the wrong ones.

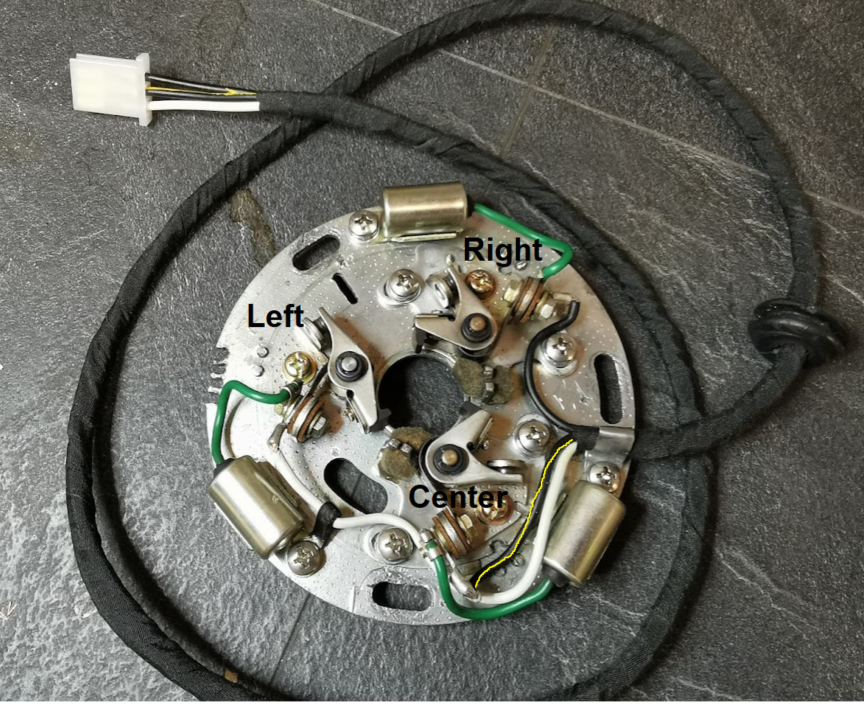

The left point is locked direct to the main plate and has therefore a different shape compare to the center and right point.

Where to start ? I found this picture below on E-bay and it looks alright compare to the wiring diagram.

The picture also gave me some idea of the cable length.

Connector:

I bought a kit from China with a lot of connectors and terminals making it possible to fit the corresponding connector in the main wiring harness.

Connection to main wiring:

Note, on the GT380 the connector goes directly to the main wiring, not through the connector plate as you see on the GT750.

I was not able to find a black wire with yellow stripe, and as you see, I painted the yellow stripe to get the color code correct.

Left point: White

Center point: Black and yellow

Right point: Black

How to fit the contact breaker and adjust the timing will come in a later post.

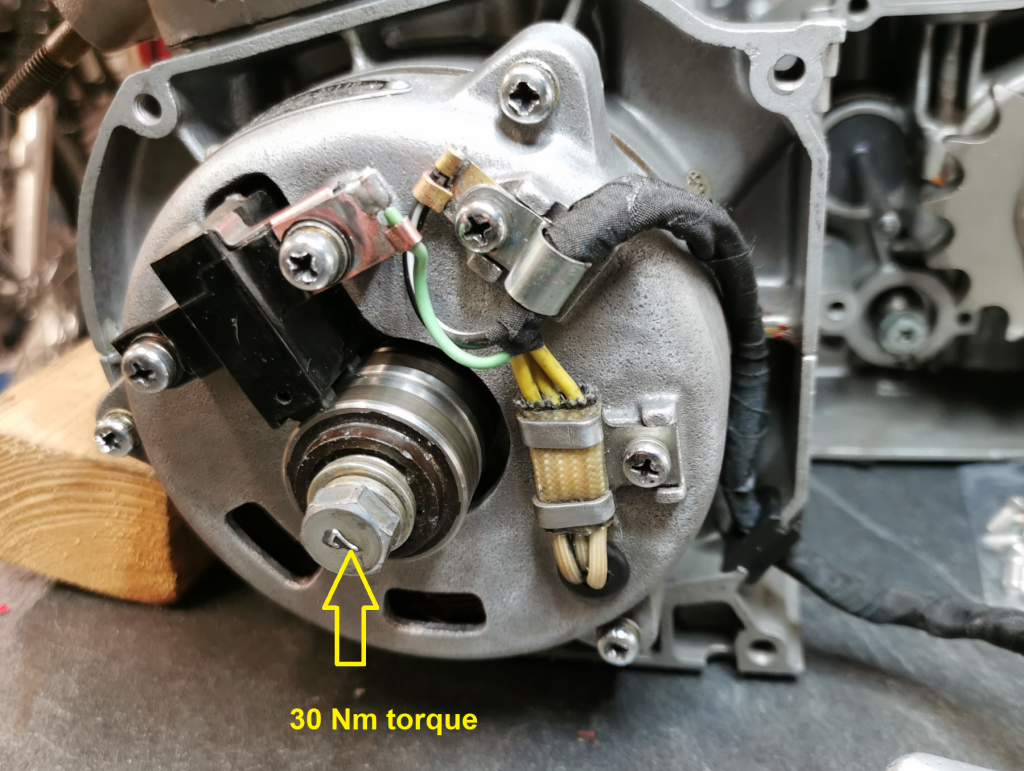

Engine side covers

Some photos from today’s work:

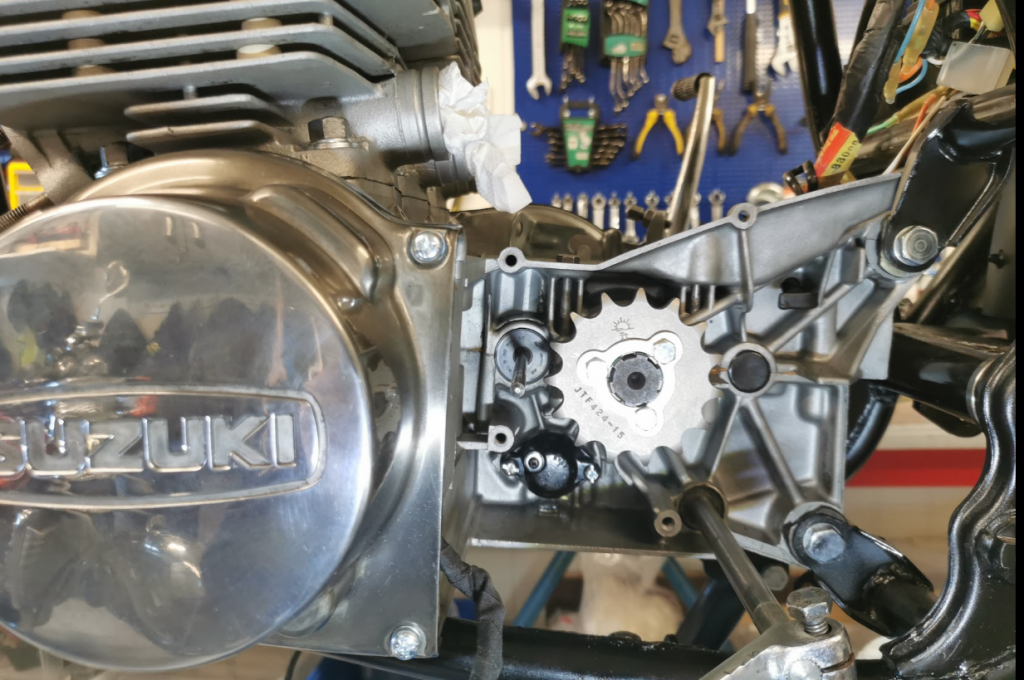

This is a trial assembly of the side cover, just to see if it all fits. The covers on top of the engine are also loose. Will be removed before I load the engine into the frame. The crank lock nut has to be tighten after the engine is bolted into the frame. I should have tighten the nut before the cylinders were mounted and blocked the rods when doing so, but now it’s to late. Will therefore lock the front sprocket when tightening the nut. Difficult to be done before the engine is bolted in the frame.

Clutch

The process of assembling the clutch is very much the same as I did on my GT750

Pictures from the GT380:

Before tightening the nut I inserted my own home made tool for locking the clutch.

50 Nm

Soaked in oil before mounting:

All good.

No torque settnings. Only at tap on the wrench after all the bolts are driven home.

Alternator for GT750 and GT380

The explanation below will be valid for both GT380 and GT750. The alternator wiring for GT750 can found on page 94 in the service manual and on page 44 for the GT380. It’s very well written and explained in the manual, but I will do it in my way and perhaps it can give you a better undrestanding of how it all works. Both manuals can be downloaded from the documents category on my blog.

Wiring diagram from the service manual:

I will use images and measurements from DENSO parts, not KOKUSAN. The differences are explained in the service manuals. The figure above from the service manual is a simplified schematics. The alternator has 36 coils (12×3) in the stator and 12 coils in the rotor (6 north poles and 6 south poles). Please see the figure below:

Abbreviation and definitions:

DC: Direct Current

AC: Alternating Current

DC Voltage : A voltage with fixed plus and minus polarity and the current will flow from plus to minus if you have a closed circurit. ( the flow of electrons are the oposite way, from minus to plus ) Ex: The 12 Volt battery on your bike is the DC voltage source and the minus pole is grounded to the frame.

AC Voltage: An alternating voltage where the polarity changes with a given frequency. On your bike the rpm + the numbers of coils in the rotor and stator will define the frequency.

Stator: The stator in the alternator above is a 3-phase generator giving 3-phase sine wave voltages phase shifted at 120 degrees.

Rotor: Ther rotor is a rotating DC controlled magnet giving magnetic flux varation to make induction of voltage at the stator windings (coils).

Regulator: The voltage regulator in the diagram is a ordinary relay with 3 positions. In postion 1 and 2 DC current will flow from the + pole on the battery through the rotor windings and down to ground.

Position 1: No restriction of the current into the rotor windings. If the voltage is too low to activate the relay, it stays in position 1, shorting the resistor. The rotor will get the maximum current and gives the maximum flux from the coils.

Position 2: The voltage has rise and ther relay activate and and the resistor be in series with the rotor windings since the short is gone and the current has to flow through the resistor and the rotor current goes down causing less flux in the coil.

Position 3: High rpm of the engine giving high voltage and the relay goes all the way to the lover postition, shorting the rotor, no current will flow in the rotor windings. There are still some flux in the iron core of the rotor and induction of voltage in the stator will still goes on. If the voltage get lower agian, the relay will go back to stage 2 or 1 and send current into the rotor windings (coils) and keeping a steady voltage to the battery.

3-phase rectifier: The rectifier turns the AC votage into a DC voltage by using 6 diodes to turn the minus part of the sine wave into a posive part. Since all three phases are appers at a different time (due to the phase shifting) the output from the rectifier will be a DC voltage with very little ripple voltages compare to a single face rectifier.

Location of parts:

YouTube links:

How an alternator works: https://www.youtube.com/watch?v=tiKH48EMgKE

How a 3-phase rectifier works: https://www.youtube.com/watch?v=-XUsu08Farw

How to test a diode: https://www.youtube.com/watch?v=mMXDa5hVzXA

Diodes explained :https://www.youtube.com/watch?v=Fwj_d3uO5g8

Refurbishing the alternator:

The alternator covered in oil and dirt, and the wiring was in a bad shape. When I was finished it looked like this:

Note: The blue wire is for the neutral indicator switch. When the switch ground the wire the indicator lamp will light.

Some of the steps:

Parts removed and the stator housing was cleaned and polished using a rotating brush.

All the terminals were polished too. Don’t forget to mount the isolation cap when assembling the brushes. If not you will short the positive pole down to ground.

The old sleeve was brittle and had to be replaced. I went for a more modern flexible type and wrapped around a textile type of tape able to withstand 150 deg C.

Bend down the locking lip of the terminal and pull out from the rear side. I did a lot of tips and tricks from YouTube how to remove the yellowing of the plastic. Used both ultrasonic cleaner and hydrogen peroxide + UV light. Not perfect, but it became better. Polished the terminals and mounted it all back in place.

Soldering:

You can replace all the wires, but I didn’t. Some of the wires were extended to make a proper wiring harness with correct lenght on all the wires. To make the soldering more easy I wrap a single wire around the wires to keep them both in place during the soldering. Added a double set of heat shrink tubings.

Mounted on the bike:

Measurements:

Stator windings:

| Bike | L1-L2 | L1-L3 | L2-L3 |

| GT750 | 0,7 ohm | 0,7 ohm | 0,7 ohm |

| GT380 | 0,7 ohm | 0,7 ohm | 0,7 ohm |

Rotor windings:

| Bike | Between green and black/white wire on GT380 and between green and ground (frame) on GT750 |

| GT750 | 5,8 ohm |

| GT380 | 6,8 ohm |

On the stator windings all measurements are done between the phases, the yellow wires.

Please notice the connectors. On the GT380 there is 6 pins and only 4 pins on the GT750. The ground (black/ white wire) and neutral indicator (blue wire) is missing. To measure the rotor on GT750 you therfore have to measure from the green wire to any GND points on the frame.

Note! If you measure rotor through the connector you will also measure through the brushes. If you get a very hight value you have bad connections in the brushes due to dirt and oxidation. Apply 12V DC for some seconds into the rotor and it will be all OK.

Numbers from the service manual:

I find those numbers hard to belive, can’t be right. The stator coil (windings) can’t vary from 0,26 ohm down to 0,1 and be valid.

Stator windings: The resistance in the stator windings don’t change over time. It’s not magic, it’s a wire winded around a some iron core and the length and thickness of the wire will define the resistance. If you get a short between some of the wires the resistance will go down and not increase. And you will see a difference between the three phases. You will never have three identical fault in the same stator. The measurements I did gave higher resistance and were identical on both the GT380 and the GT750.

Rotor windings:

The rotor resistance I measured on both GT750 and GT380 is much lower compare to the manual. OK, one reason can be a short between windings in the rotor. But i checked all 12 magnets and verified they all had the correct Norh and South poles with the same strenght. A short giving half the resitance compare to the number in the manual would give weak magnetic field on some of the magnets. Since I have about the same measuremetns on both rotors and the GT750 is running fine and gives the correct voltage to the battery I’m pretty sure it’s all OK. Why the numbers in the manual are so differnt, I really don’t know.