Assembling the clutch and the kick starter

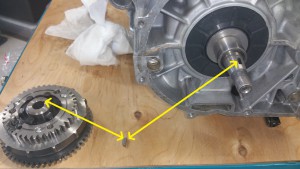

The photo below shows how I did the assembly of the clutch and the kick starter.

Step 1: Fit the oil guide plate. Drive all three screws well home. If you are to use thread locker or not depends on your religion. Do you believe in it or not. Someone says ” don’t use it, you will never get them loose”. Others say….And I’m not gonna tell you what I did .

Step 2:

Mount the shim ( no.16)

Step 3:

Mount the spacer, chamfer side goes in back.

Step 4:

Mount the clutch

Step 5:

Mount the bearing assembly

Step 6:

Mount the spacer, chamfer side at the front.

Step 7:

Mount the clutch sleeve hub (5), locking washer (7) and center nut (6)

Always use a new locking washer, not the old one like I did on the photo.Why did I use the old one ? I didn’t know I had a new one until I had completed the assembly process. Can save the washer for the next time.

Step 8:

Torque setting for the center nut is about 50 Nm.

Before torquing up the center nut you need to some how lock the sleeve hub (5) Never use a screwdriver on the edges. You can make a special tool using old steel plates from a clutch. I had no such tool but did it in this way:

Lock into one of the gears and do something clever to lock the front sprocket, like I did on the photo above.

Don’t forget to bend the “new” lock washer. One of the edges is enough.

Step 9:

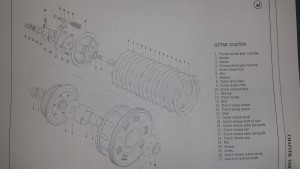

Before mounting the clutch check the specifications of the cork plates and the springs

STD lenght: 40,4mm. Spring setting limit :1,4mm

STD thickness: 2,9-3,1mm. Wear limit: 0,2mm

Let the cork plates be quite oily before you mount them

Grind off any layers from the steel plates.

Start with the cork plate, then the steel plate. The last plate should be a cork plate. The steel plate has a little radius on one side and a flat side on the other side. The flat side at the bottom and the radius facing against the front.

8 cork plates and 7 steel plates.

And as you can see, I found the new lock washer after I had completed the assembly.

Step 10:

Mounting the clutch pressure disk.

Remeber the mount the clutch release shaft (17)

Mount the bolts in a pattern for an even distribution of the force. When all bolts are driven home you just give it a tap . No torque settings

Step 11

Kick starter

Mount the spring holder (and the plate behind if not already mounted)

Mount the spring

Competed !

Step 12

Mounting oil seals, gasket and side cover

There are two oil seals in the cover, both should / can ( depends on age) be replaced. Add grease on the seal side.

I found both mounting studs quite stuck in the cover, not at the case side. Therefore I put the gasket at the cover side.

Done !

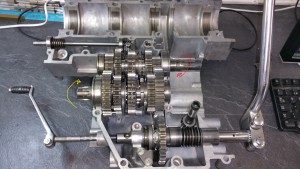

Kick Starter Sequence

Here is the sequence of the kickstarter. I had to assemble without paying attention to the alignment marks, because one of them is not present. ( look at my privious post )

Both punch marks at the end of the axle and the kick starter are present and aligned.

See the punch marks at the yellow and green arrows.

Sequence 1 Klick on the images for details

The front shaft is connected to the clutch and will rotate like the red arrow shows.

The rear shaft is connected to the front sprocket and will rotate like the yellow arrow shows.

The little clutch on the kick starter shaft is in released position and is not in contact with the rotating gears.

The oil guide hole is also facing upwards. Everything should be okay.

Sequence 2

The engine is stopped and we try to restart the engine by kicking down.

The little clutch will connect and the rotations on the shafts will be according to the yellow arrows. And of course, in the same direction as while the engine is running.

When the kick starter is released it all goes back to sequence 1

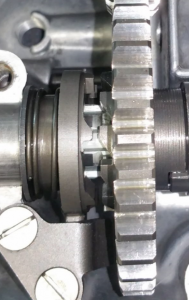

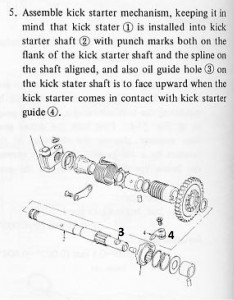

Kick Starter

This was a bit tricky, I need some FB help to verify my assumptions.

As far as I understand this is the correct assembly of the kick starter.

The oil guide hole (3 in the drawing below) is facing upwards and the kick starter is in contact with the kick starter quide 4.

In this position the motor can run and the kick starter is in released position, free from any contackt with the gears. See the next picture.

No contact with the gears.

So far so good, but now it all fells apart ? Map and terrain does not fit anymore.

In all manuals and also on the DVD from the Kettle clinic it shows a punch mark on the starter shaft and the spline on the shaft. They have to be aligned. If I do so it all comes out wrong and the oil guide is not longer facing upward when the kick starter is in contackt with the kick starter guide.

It looks like it’s only a punch mark on the kick starter shaft on my bike. The second mark is difficult to find. There are som scratches and a groove but nothing like a punch mark. See the next picuture. (click on the image for details)

If I align according to the orange arrow the facing of the oil guide hole comes out wrong.

Compare the assembly against the instructions at the DVD.

If I don’t care about the punch mark and try to mount according to the DVD from the Kettle Clinic it looks alright. The oil guide will face upwards as it should when the kick starter is in released position ( disconnected from the gears )

Please give me some feedback about this issue. When I’m 100% sure it’s all correct I might post a video showing the entire sequence of the kick starter in action.