Removal of the cylinder

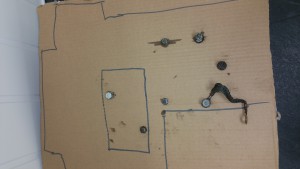

The cylinder is often stuck to the case and studs due to 30-40 years of rust. Using a thick steel plate with holes for attaching the cylider might solve the issue

Screw down the bolts down onto the studs who are connected to the case.

fasten the steel plate to the cylinder with screws

Gently screw the bolts one at a time, little by little until you have a “lift off” and the cylinder is loose.

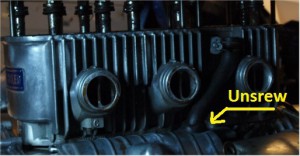

Note: Remove the nut underneath the intake in the middle (right hand side of the tube). I didn’t and ruined the cylinder. Luckily I got hold of a new and better cylinder.

Lesson learned: Build yourself a man cave with better lighting and more space.

Engine removal

Engine removal :

A one man job if you do some preparation up front. Lift the engine and slide it easy out on the right hand side.

Engine on the table :

A chain block and some pieces of wood, the engine is ready for surgery. My back is still in a good shape due to some thinking before lifting. Much better to do the work indoors. Winter will soon come in Norway. Now I can spend quality time in a warm and cosy basement working on my GT

Preparing for engine removal

Today I have done the following

Disconnected wires from

1. Gear indicator

2. Timing points

3. Generator

4. Disconnected tubes from the radiator.

5. Disconnected tube from the 2-stroke oil reservoir

6. Mounted a frame of wood to support the engine.

7. Remove right footrest

8. Removed left side stand

9. Removed the brake pedal

Engine overhaul

Time for engine overhaul. Two years after I restored my A model I have to get new crankshaft sealings. Last time I had focus on the frame and paint work and didn’t know about the bad shape of the crank. The time frame doesn’t matter. I look upon this work as a therapy. I assume I will learn a lot of this project and it will keep me happy through a cold winter in Norway. Hopefully the kettle will be on the road next spring / summer.