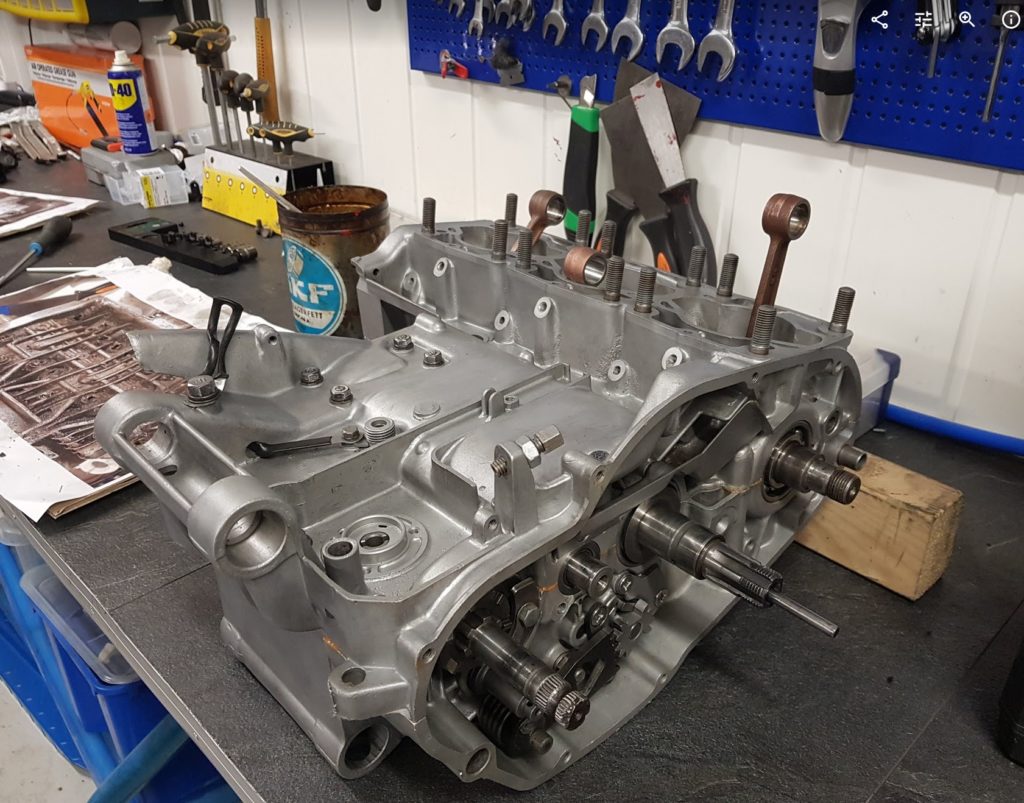

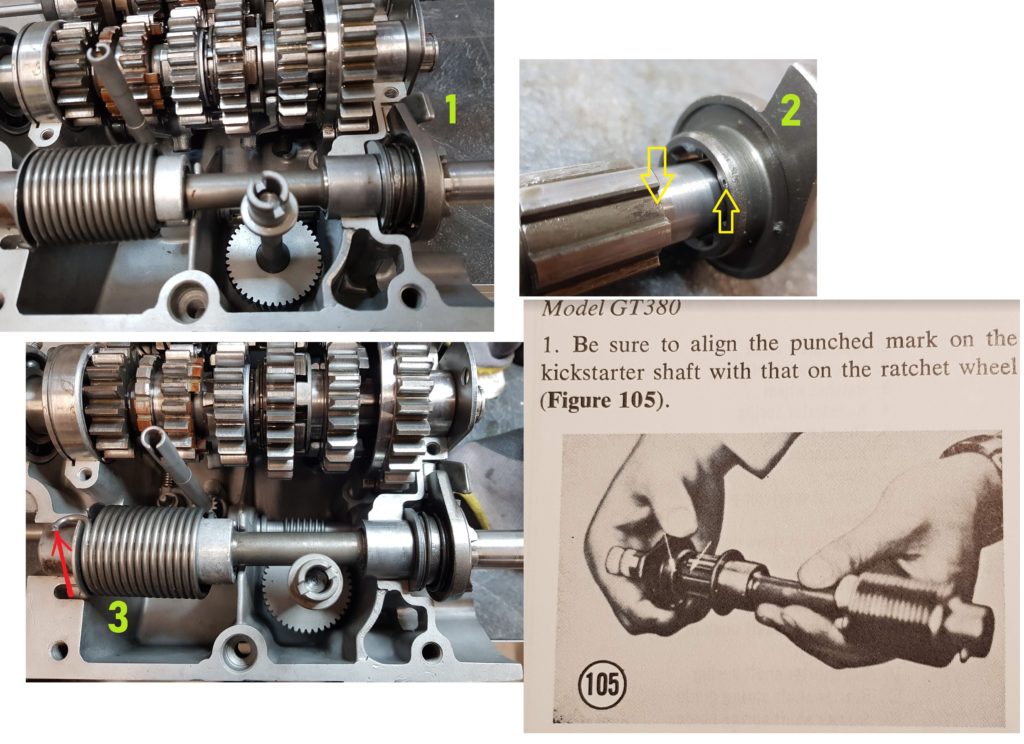

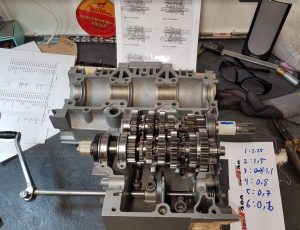

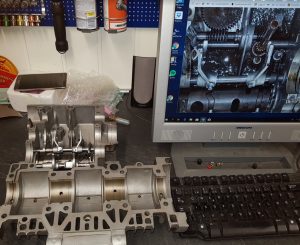

After months of doing nothing on the GT380 I’m now back on track. This fall has been very busy and I had to focus all on work and not much spare time to invest on my GT380. Hopefully it will be better the following winter and spring.

Two weeks of Christmas vacation has been good and I was able to get some steps further on the project, but then…..I spotted a disaster.

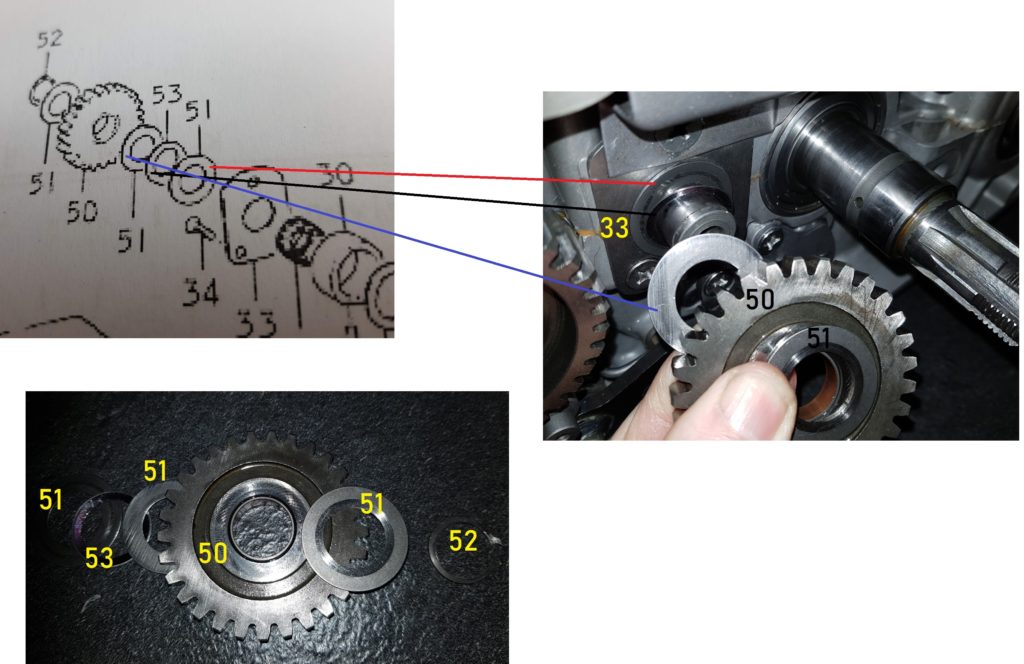

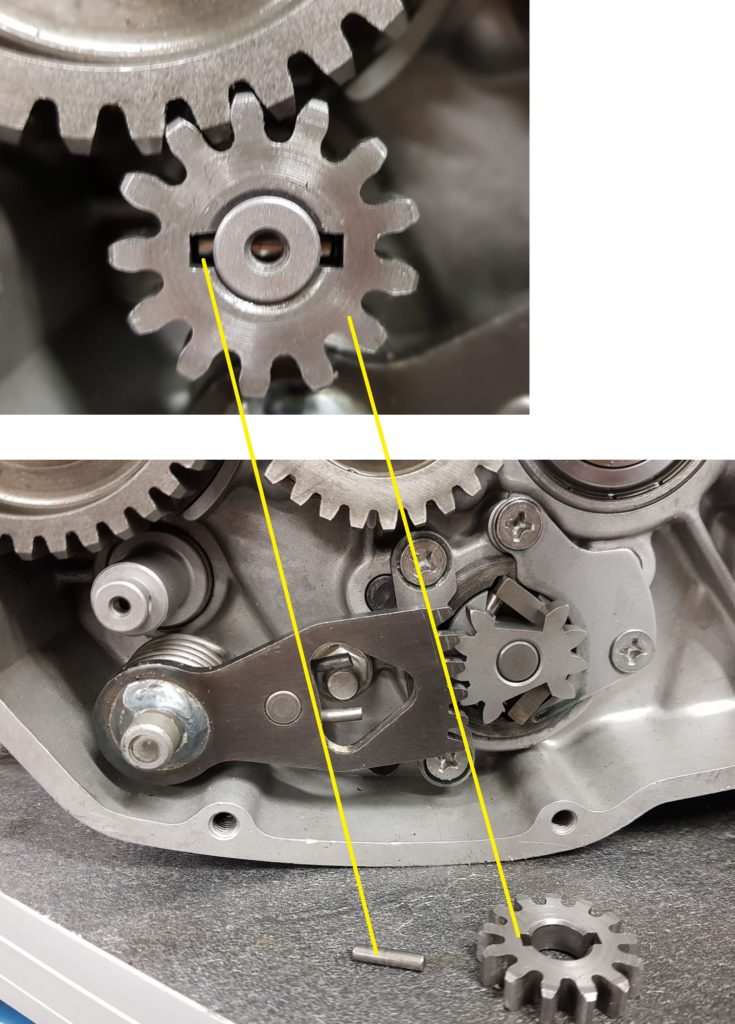

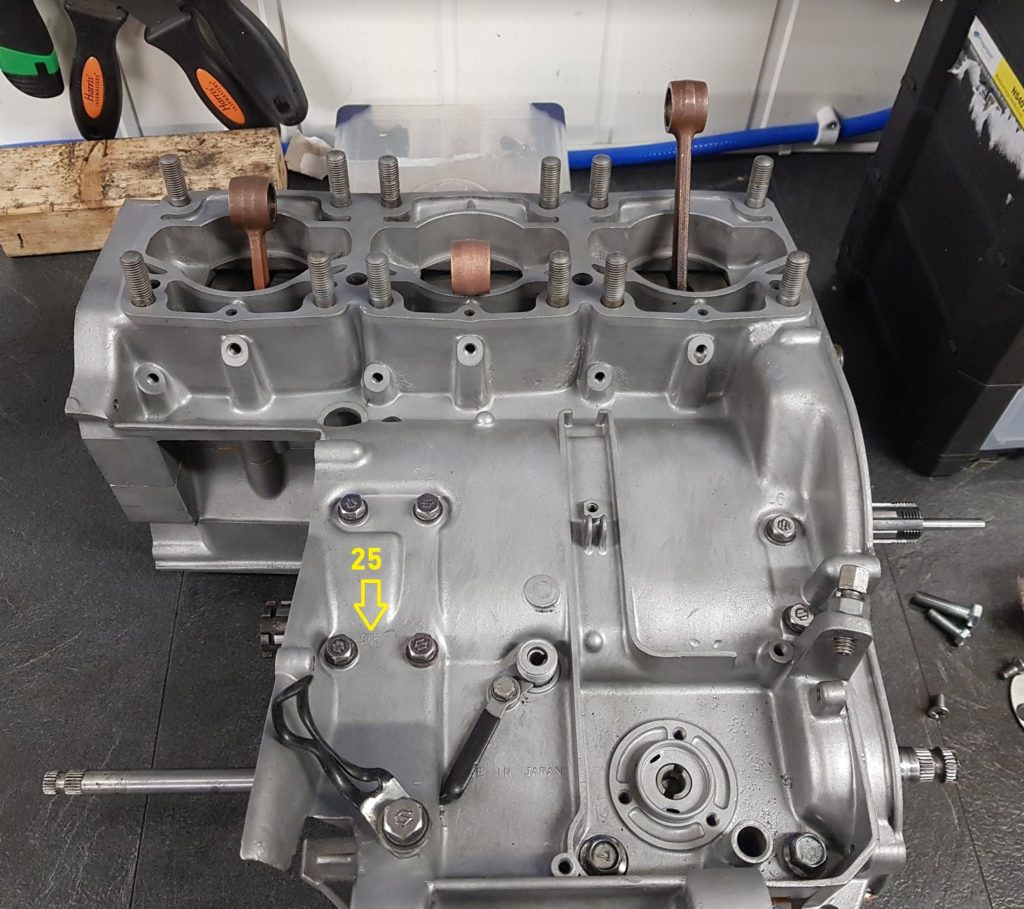

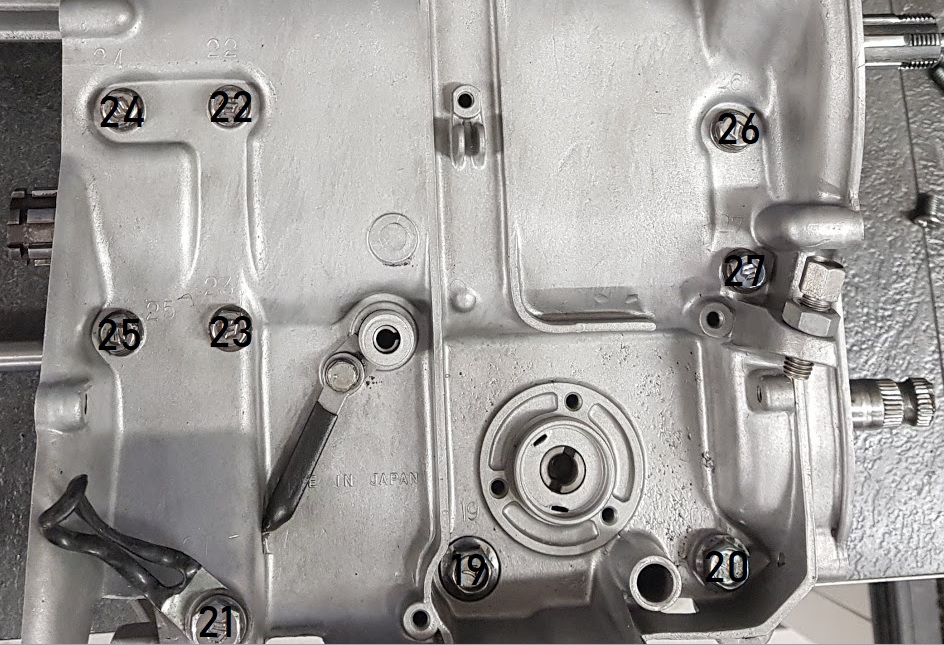

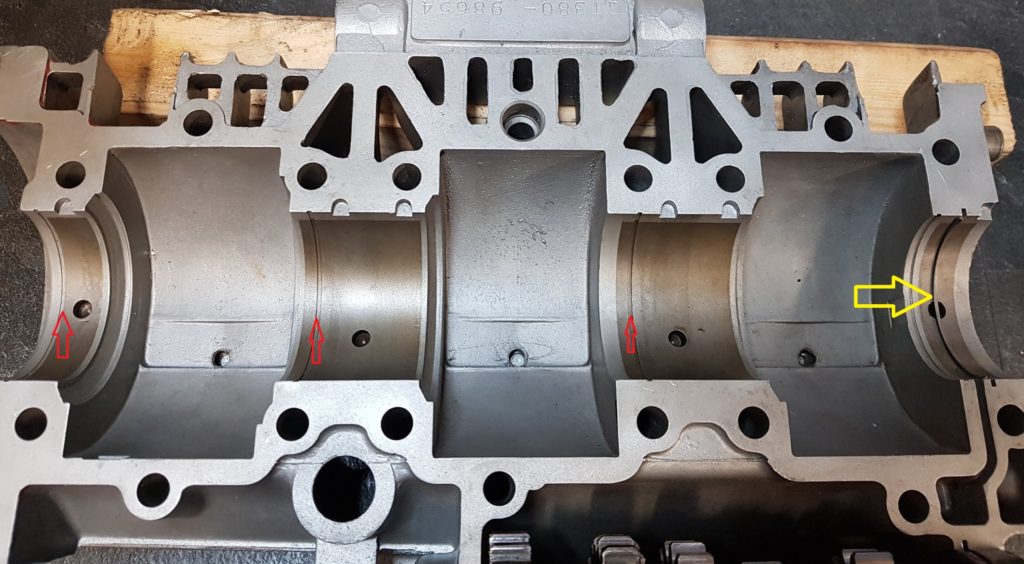

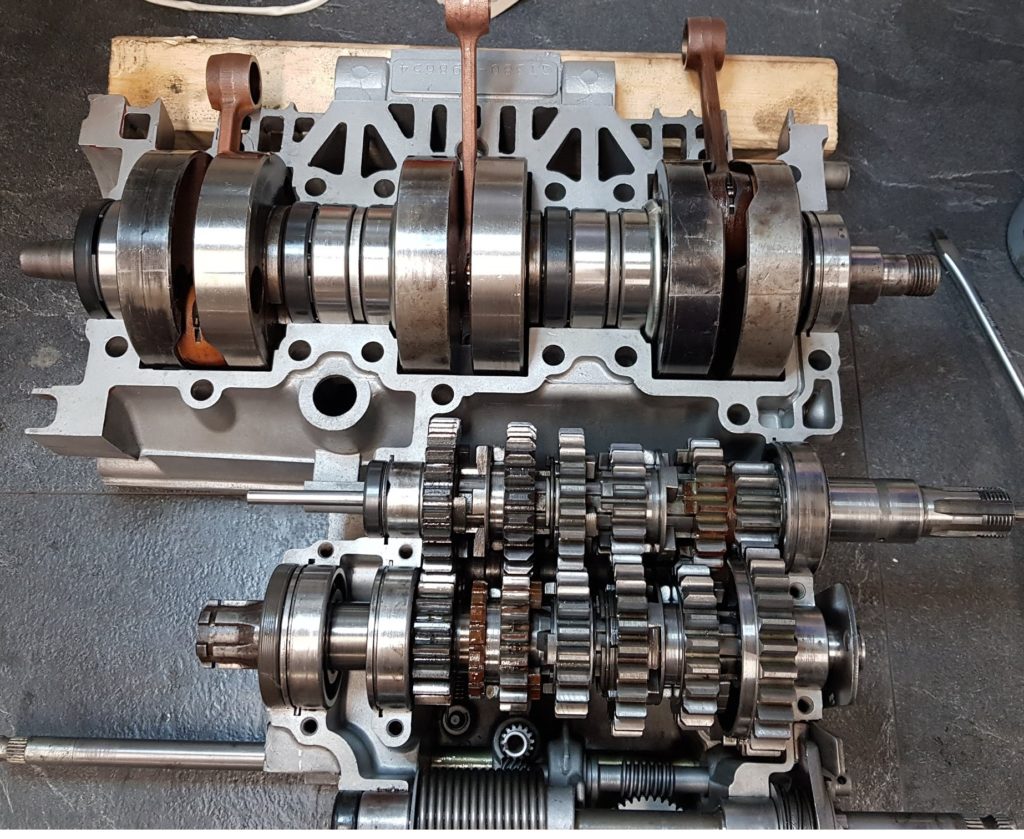

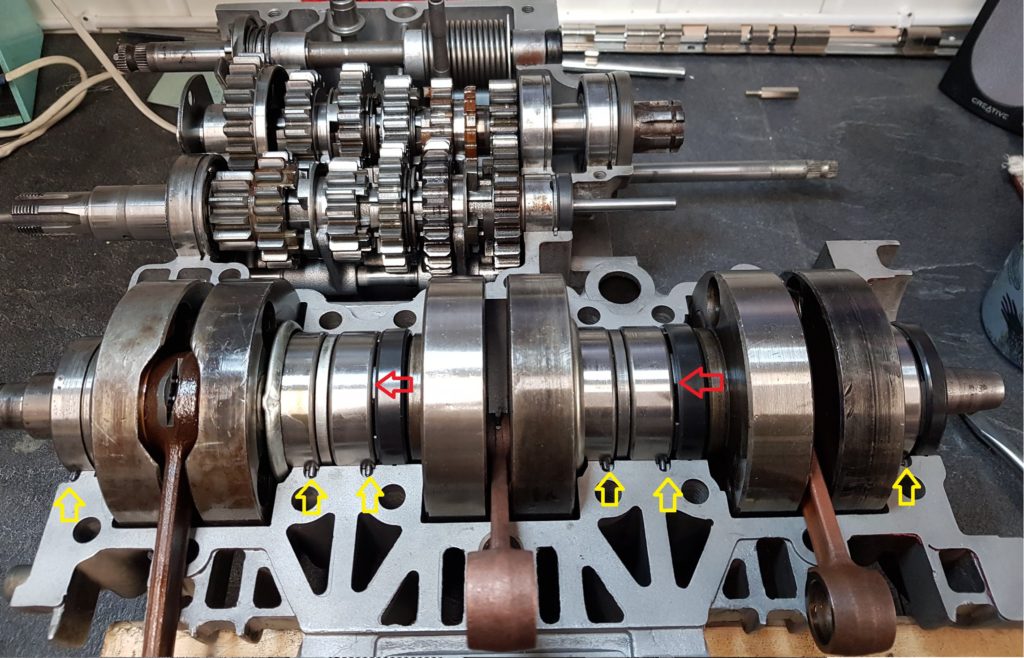

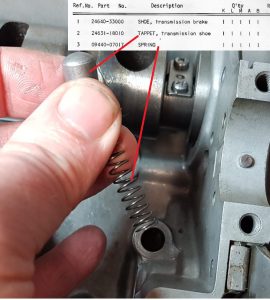

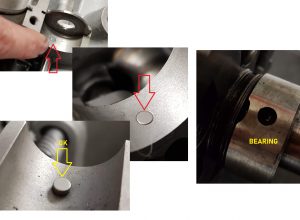

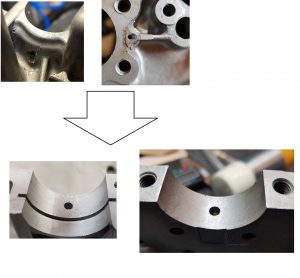

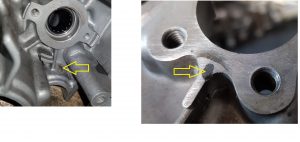

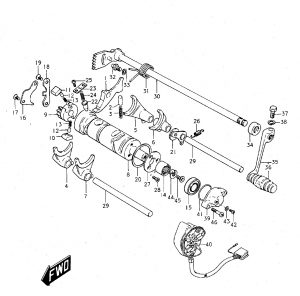

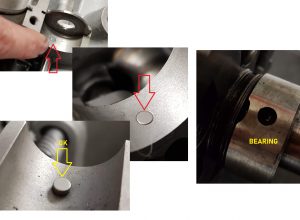

Two of the lock pins holding the bearings at the gear shaft in place were squeezed all the way down into the crankcase. I should have spotted this at a previous stage, but what now. Is it game over. Do I have to get a new case ? Cracks on the other sides as well due to the brutal force into the aluminum.

Previous owner must have done this without thinking properly before assembling the engine. And on both gear axles…This is what happens when you rush into unknown stuff without taking the time needed to think twice and think it through.

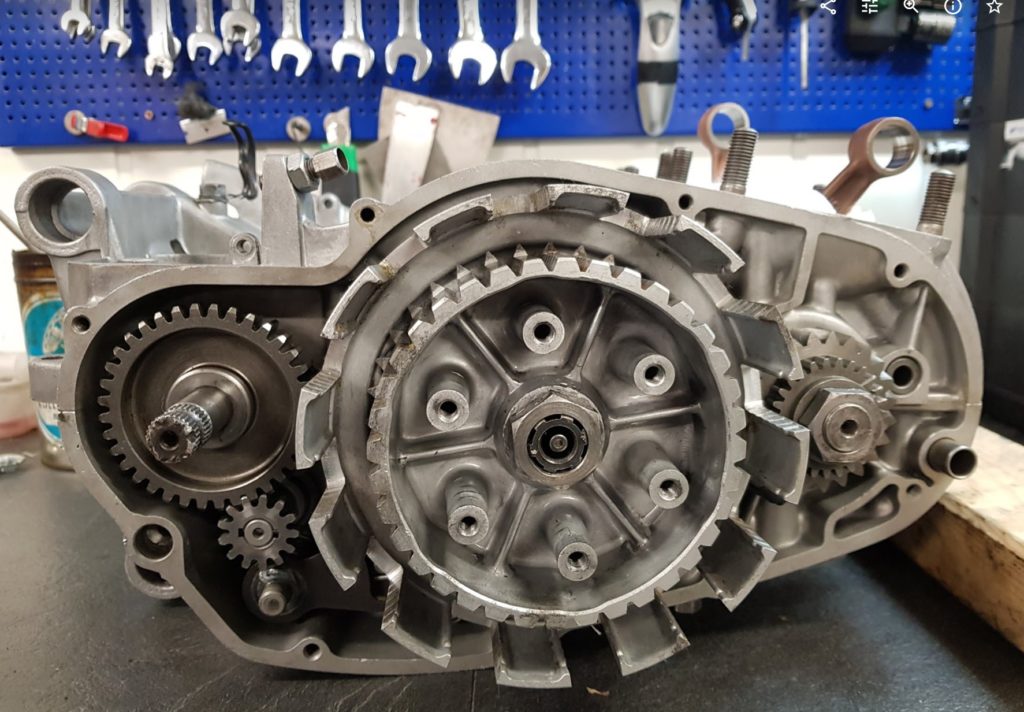

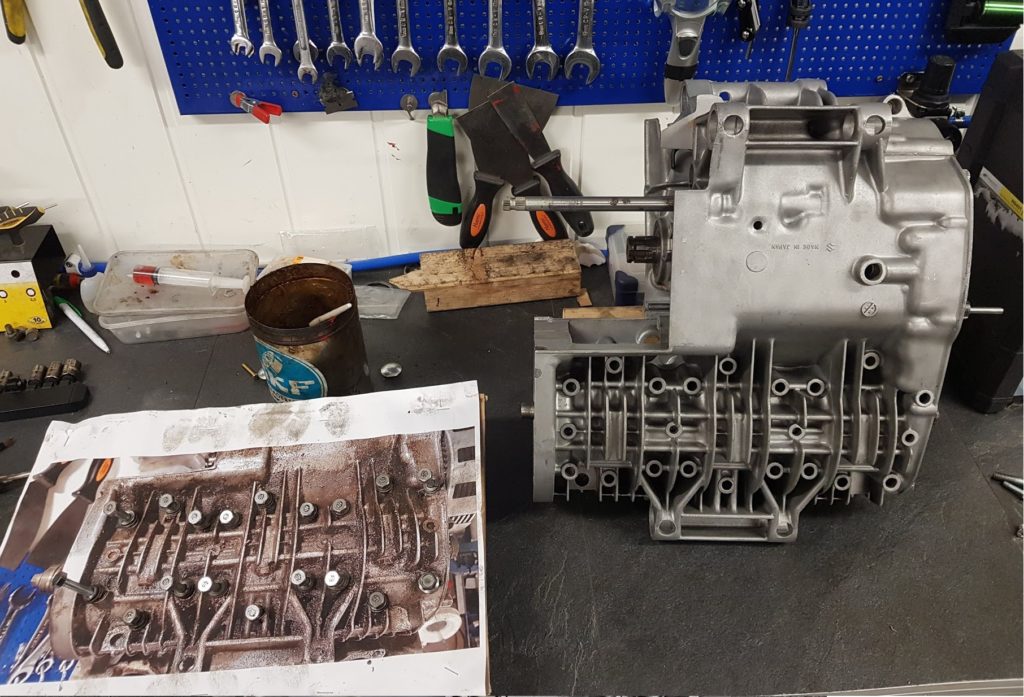

I have a spare engine I can use, but consider all the work I had put into this it’s worth giving it a try to fix this one. And if it works I will still have two GT380 engines. This is how i did it :

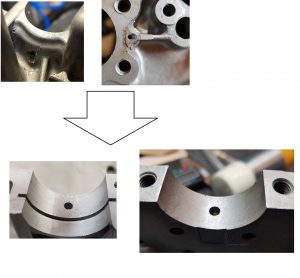

Step 1:

Drilled and milled holes at the rear side and was able to push the pins out.

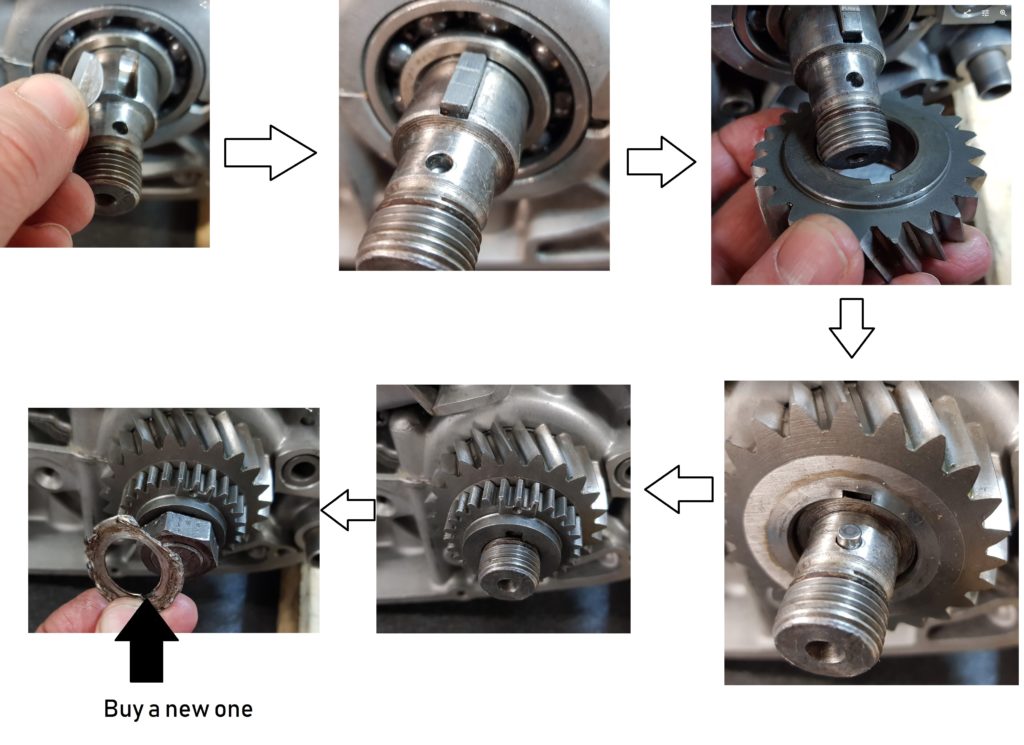

Step 2:

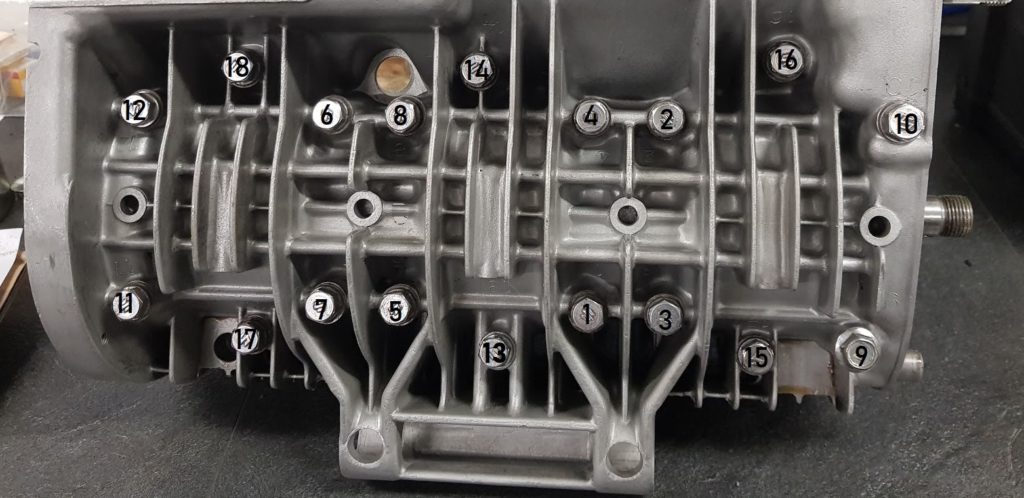

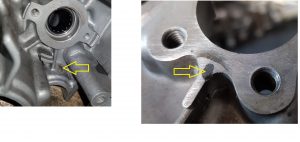

Drilled 2,5mm hole from the top side. Threaded 3mm and inserted a set screw and adjusted to the correct depth.

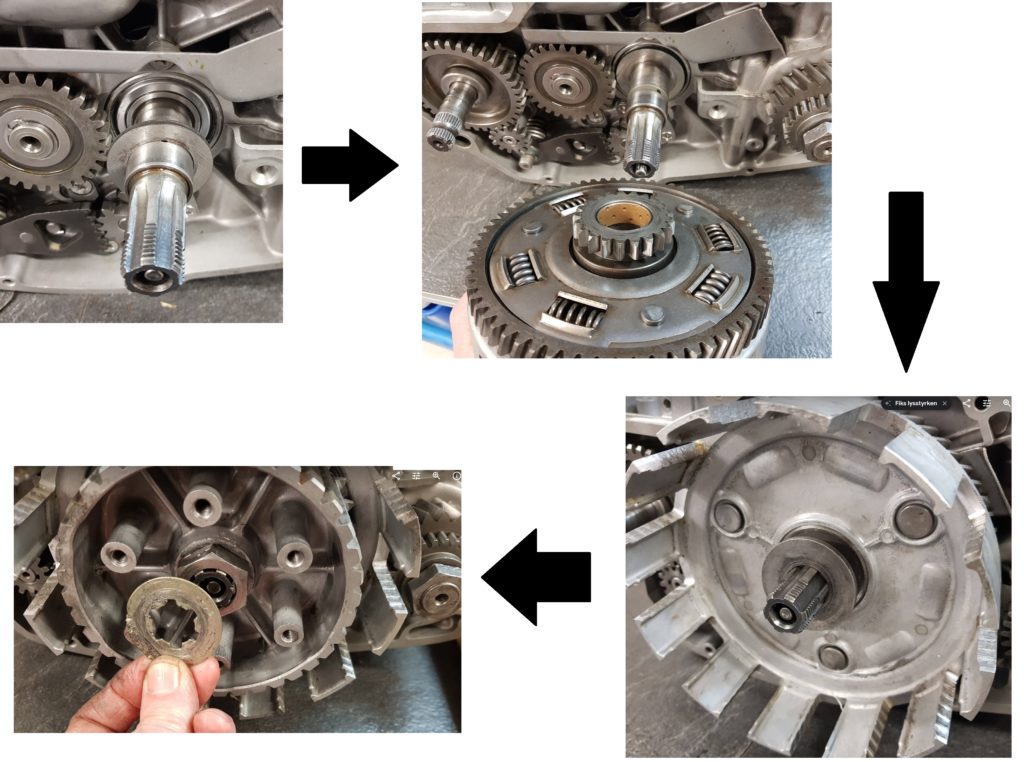

Step 3:

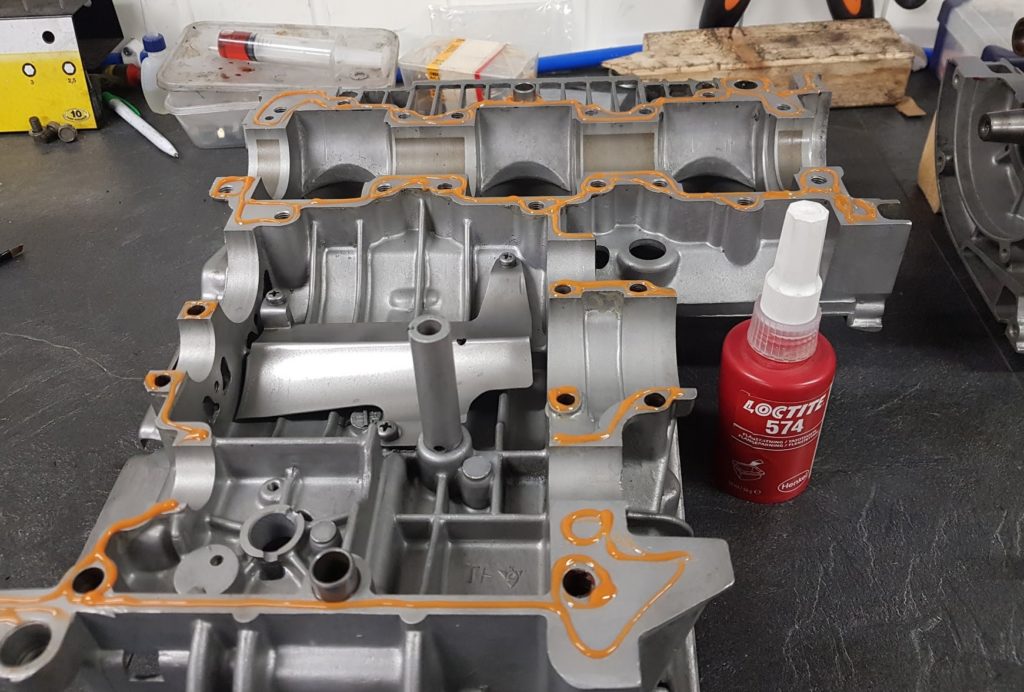

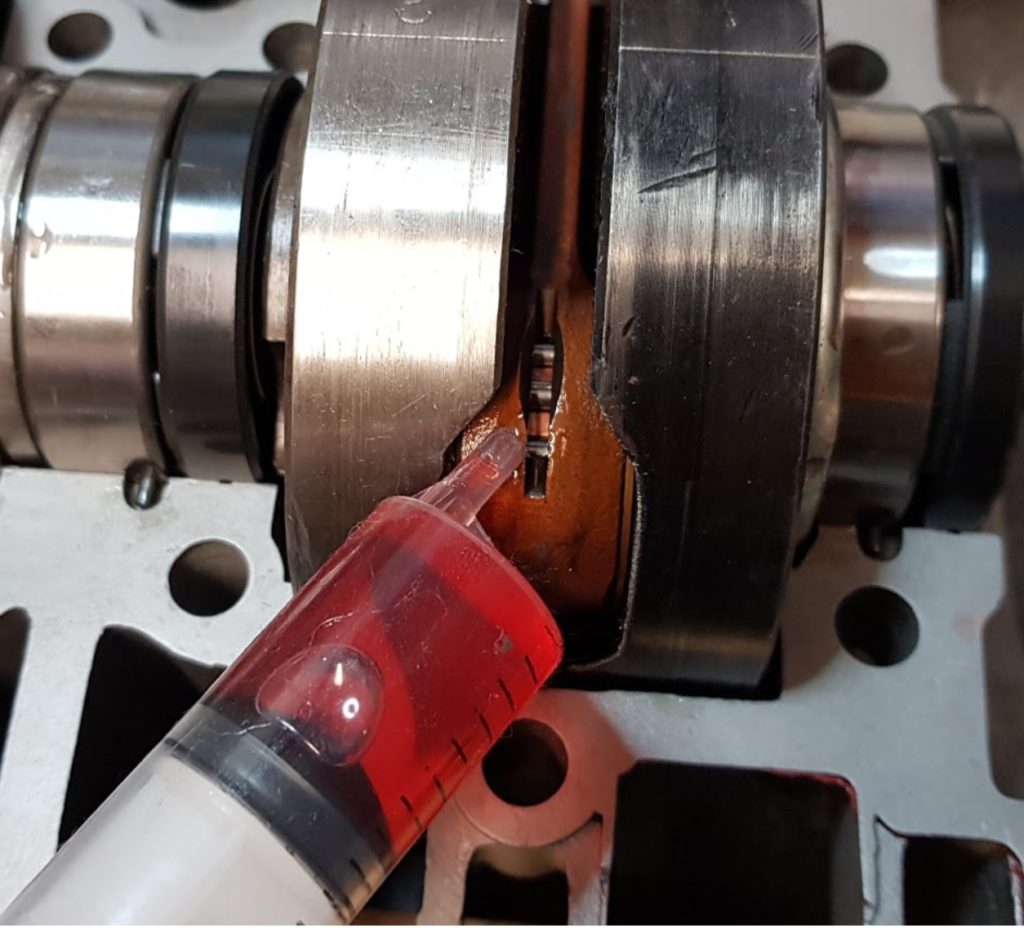

Gluing using Speedy-Fix

If something is too good to be true, .. it’s not true. That was also what I thought about Speedy-Fix, cost nothing from E-bay. Can it work ? Yes, I have tested it extensively on plastic, wood and metal. It really works. A totally damage plastic side cover was saved using this powder and hardener.

I could have TIG welded a tap onto the pin and pulled it out, but I don’t have any welding tools. Since the aluminium already had cracks I don’t think it added much structural damages to do the drilling and milling. A lot of materials left and if the gluing fails the set screw will still be in place.